It is a fact that modeling for 3D Printing is quite confusing. People apply various software using different materials and printing technologies. So you might get lost, and it seems impossible to design an accurate 3D model for 3D Printing.

This post includes the common mistakes that should be avoided when turning the 3D model into 3D print:

Disregarding the Material Guidelines

Materials used in the process varies. Some are flexible or robust, light or heavy, strong or brittle, rough or smooth, and others. Also, you design an object based on the specific material. The printing material pre-determines the basic design guidelines you should stick to.

The resolve this mistake, it is a must that you stick to the design rules of the material that is vital for successful Printing. You should read the design guides first before you start working on your model.

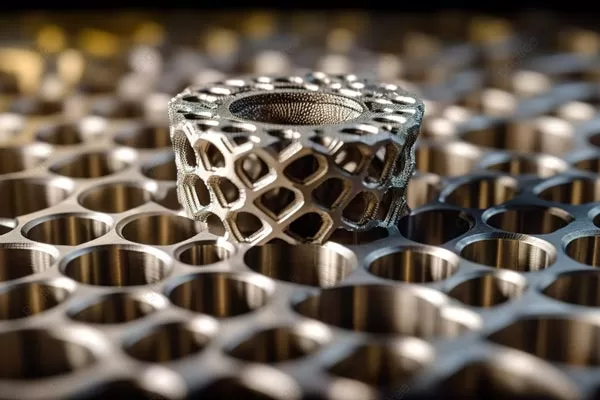

Metal 3d printing parts

Giving Less Attention to Printing Technology

It is not just the essential chemical attributes of the printing materials that are different, but the technologies use for printing as well. Printing interlocking parts using gold, bronze, silver, or resin is not possible. You can use only ABS, Aluminum, Rubber-like, or polyamide. It is not because of the material but of the printing technology applied for each material.

For ABS, it is best to use fused-deposition modeling with an added nozzle and other materials for support. For resins, use the SLA or stereolithography for the best result.

Disregarding Wall Thickness

The common reason why some 3D models are not printable is because of the issues concerning wall thickness. Some wall thickness is too thin. If the walls are too thin, it is hard for the small parts to print the model as they become very fragile. In some cases, where the walls are too thick, it causes too much internal stress and might cause the item to crack or may lead to breakage.

Ignoring File Resolution

The usual file format for 3D Printing is STL, which means standard triangle language. Your design will be translated into triangles. Many 3D modeling software can convert the design to STL file and fix the desired resolution.

Paying Less Attention to Software Guidelines

There are lots of different 3D modeling software packages. Some are for developing 3D prints, and others are used by 3D artists that may need additional editing before they can provide a 3D model for Printing. For instance, applying a wall thickness is automatic, but for some, it may require to be set up manually. Using a beginner-friendly software could help for 3D Printing, but you might still encounter some difficulty in creating a hollow model.

3D Printing may sound more complicated than they are. However, if you know your software and choose the right material, you can go along with it smoothly. If you have difficulty in learning how to 3D model, you can always search online or get in touch with the experts.