With the introduction of modern-day tooling guides, producing more and more prototypes has now become easier and safer too. When trying to bring some hacks to notice, the latest trend-setter has been the use of rapid tooling. This process refers to the use of “prototyping techniques”, which are then mixed with conventional practices, just for the production of various industrial parts. These products are rather functional by means of a CAD database, which analyses the natures of the parts produced and makes it possible for industrial consumption. In other words, when compared to the traditional practices of producing molded parts, the results of rapid prototyping and tooling, were much more significant!

The Categories and Usefulness of Rapid Tooling:

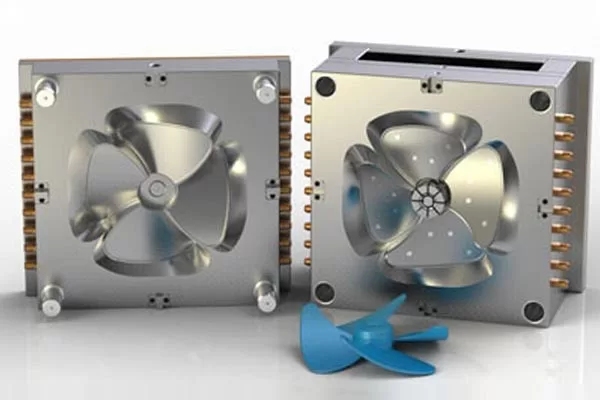

This new programming phenomenon of rapid tooling is able to take industrial experts to a whole new world of production and manufacturing. The mold is not only developed quickly, but the models are prepared within a less amount of time, within a relatively lower cost. On this note, there are two categories of this process mentioned. They are as follows:

- The indirect method, which is also known as the pattern-based practice, refers to the use of “master-patterning techniques” to produce effective molds. This technique may take a little time, due to the design or pattern, which has to be introduced here.

- On the other hand, the direct method of this practice indicates the use of additives, which actually helps in making molds, used for all sorts of industrial purposes. Although the features of it vary, the results are more or less similar! The powdered metal is layered in a downward motion. The platform is kept on the lower angular position, till the mold is produced.

Rapid tooling molds

A Quick Note on the Advantages of Rapid Tooling:

The case of rapid tooling is better for bulk industrial production. That is why, some of the specific advantages that you can take note of, are as follows:

- The use of this process helps in better insertions. When building the core here, the results are updated and productive as well.

- The products of prototyping are delivered fast. This means that there is no delay when sending the products to the market.

- The rapid tooling products are basically available within a lower price range. This is all due to the lower costs of production, and less interference of manual labor.

- In addition to the above, the results likely bring forth the availability of mature products. Even the list is diversified, as production scale increases.

- The need for this procedure is less. Hence, capital investment is also low.

- When problems of troubleshooting arise, this procedure can be tried as well.

- The diversity of products manufactured is all because of the use of several types of raw materials. This is more or less restricted in traditional methods.

Considering all of the above advantages, this method can be used to produce all sorts of molds for every commercial and industrial sector. Just some basic rules to follow and you are good to go!