In the landscape of modern manufacturing and prototyping, few technologies have sparked as much excitement and innovation as 3D printing. From rapid prototyping to custom manufacturing, 3D printing services have revolutionized the way businesses bring their ideas to life. Let’s delve into the fascinating world of 3D printing services and explore how they are reshaping industries and empowering creators worldwide.

The Evolution of 3D Printing Services

Born out of the intersection of technology and creativity, 3D printing, also known as additive manufacturing, has undergone rapid advancements since its inception. Originally developed for rapid prototyping in the 1980s, 3D printing has evolved into a versatile tool capable of producing complex geometries, functional prototypes, end-use parts, and even customized consumer products.

Understanding 3D Printing Technology

At its core, 3D printing builds objects layer by layer from digital designs, using materials such as plastics, metals, ceramics, and composites. There are various 3D printing technologies available, each offering unique advantages in terms of speed, accuracy, material compatibility, and application suitability.

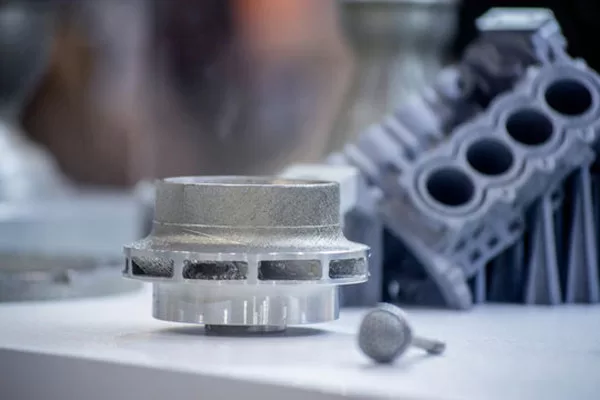

Metal-3d-printed-parts

Some of the most common 3D printing technologies include:

Fused Deposition Modeling (FDM): This popular method involves extruding thermoplastic filaments layer by layer to build up the desired object. FDM is known for its affordability, ease of use, and versatility, making it a favorite among hobbyists, educators, and small businesses.

Stereolithography (SLA): SLA uses a UV laser to cure liquid resin into solid layers, producing highly detailed and smooth parts with exceptional surface finish. It is widely used in industries such as jewelry, dentistry, and engineering, where precision and aesthetics are paramount.

Selective Laser Sintering (SLS): SLS utilizes a high-powered laser to sinter powdered materials, such as nylon or metal, into solid layers. This technology is prized for its ability to produce robust and functional parts with complex geometries, making it ideal for aerospace, automotive, and medical applications.

Direct Metal Laser Sintering (DMLS): DMLS is a variant of SLS that specifically works with metal powders, enabling the production of high-strength, fully dense metal parts directly from digital designs. It is widely used in aerospace, defense, and medical industries for manufacturing lightweight, complex components.

The Benefits of 3D Printing Services

- Rapid Prototyping: One of the primary advantages of 3D printing services is rapid prototyping. Design iterations that once took weeks or months can now be produced in a matter of days, allowing businesses to accelerate the product development cycle and bring ideas to market faster.

- Cost-Effective Customization: 3D printing enables on-demand manufacturing of custom parts and products without the need for expensive tooling or molds. This level of customization is particularly valuable for niche markets, personalized products, and low-volume production runs.

- Complexity Without Compromise: Unlike traditional manufacturing methods, which may struggle with complex geometries and intricate designs, 3D printing excels at producing parts with virtually unlimited complexity. This freedom of design allows engineers and designers to push the boundaries of innovation without compromising on functionality or aesthetics.

Conclusion: Shaping the Future of Manufacturing

As technology continues to advance and the capabilities of 3D printing expand, the future of manufacturing looks brighter than ever before. 3D printing services have democratized access to advanced manufacturing capabilities, empowering entrepreneurs, innovators, and businesses of all sizes to turn their ideas into reality with unprecedented speed, precision, and efficiency. As we continue to push the boundaries of what’s possible, one thing is clear: the era of 3D printing is here to stay, reshaping industries, transforming supply chains, and unlocking new opportunities for creativity and innovation on a global scale.