Is your company looking to use low-volume manufacturing? If yes, then you’ll be glad to know that this production technique comes with a myriad of benefits for both mid and low-volume production sectors.

The use of this technique has been on the rise just like CNC machining and 3D printing, low-volume production has emerged as a serious contender when it comes to the creation of different parts, products, and prototypes.

When it comes to prototype designs, the competition in this field is so stiff that start-ups won’t progress as anticipated if they don’t incorporate low-volume manufacturing into their production process.

Clients want customization according to their individual preferences and specifications as they want the best and high-quality tools and products at an unbeatable process. Well, you’ll be glad to know that low-volume manufacturing can help different sizes and ranges of companies.

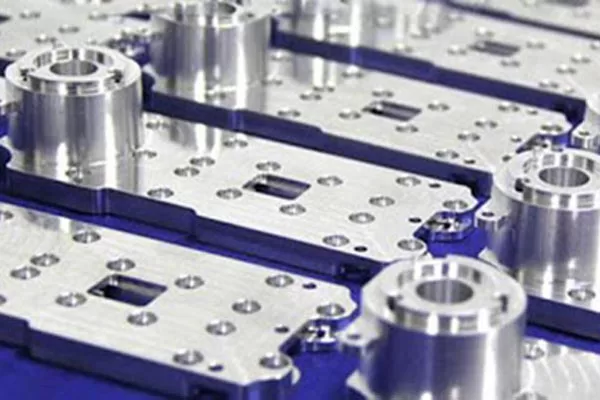

CNC aluminum parts

Regardless of whether you are a large-sized or small company, low-volume production will be beneficial to you in every step of production.

Low-volume production saves time and money

If you are looking to save money and make the entire production process cost-effective, then low-volume manufacturing should be at the top of your list. Buying parts and products in bulk is not always a sound investment decision, thus the reason why people are slowly gravitating away from bulk orders.

More and more people are looking towards product customization as they pay key attention to details, thus the reason why they opt for low-volume production. Customization of a high-quality product can be quite expensive especially for large companies.

If money is an issue, then low-volume production is the perfect option. With this technique, you’ll be able to create a high-quality product while still using the best manufacturing service.

When it comes to the creation of a quality product, then it’s up to the client and manufacturer to deliver an excellent product that will offer huge profit margins and low-volume production is the perfect option for that.

The production technique will meet all the demands of the user’s orders meaning there will be fewer overhead costs. Your parts and products will be created as per the demand scale. With low-volume production, there will be also less wastage thus making your production process economical and profitable.

Attaining product design flexibility

In the modern manufacturing world, most producers are looking for innovative and fresh designs to cater to the ever-changing needs of their clients. When it comes to providing a certain degree of design flexibility to your product designs, low-volume manufacturing is amongst the techniques that do so.

Flexibility allows companies to enjoy better economies of scale as they will be able to get high-quality products at affordable prices. One of the best things about this technique is it allows room for customer feedback providing you with the opportunity to make improvements on various aspects of production.

If there are design changes, you’ll be able to correct them without using a lot of resources and money. There are different variations of products created by low-volume manufacturing allowing for testing of the product that will meet all the needs and requirements of your clients.