Rapid prototyping is crucial for anyone looking to sell their products faster. With rapid prototyping, the parts used in designing any product will become available without any further delays. In this current dispensation, you’ll find a plethora of innovative technologies sweeping across the globe. One of the best rapid prototyping strategies available today can always help in the designing of products without stress.

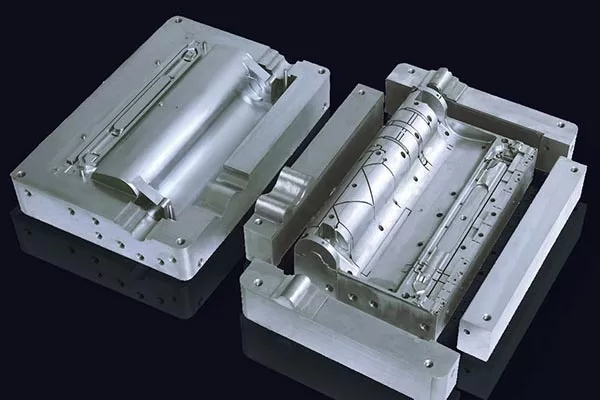

The name of this excellent production technique that can help in product manufacturing is known as rapid tooling. With this process, it’s easier to design products and parts faster than anticipated. It helps in the validation and testing of parts before engaging in the full production procedure. Rapid tooling has several incredible names such as prototype mold, soft prototyping, and prototypes tooling.

Rapid Tooling Helps for Innovation:

One of the best advantages of using rapid tooling is to help in providing innovation opportunities. With this production process, there is no further need to make use of conventional tooling ideas. It can create several innovative opportunities that help in the development of products and parts. Studies have shown that traditional prototyping may require a lot of time and money. It’s because the stress of designing prototype tooling and other items to suit the accurate tolerance may be difficult to achieve. Using rapid tooling will help producers and developers to design difficult geometries that may prove impossible for conventional approaches.

This Production Method Will Save Time:

There is no argument about the time-saving features of rapid tooling. It’s because people have to create special tools, patterns, or molds to develop products. With prototype tooling, there is always time reduction from the evaluation and initial idea. The end prototypes remains perfect and prepared for testing performance, usability, features, and forms. On the feedback, it’s always possible to change the product design. With a fast turnaround, a surviving company can stand out from the crowd and deliver quality products.

Rapid tooling products

Rapid Tooling Remains Cost Saving:

Cost savings cannot be ignored when talking about rapid tooling. The truth is that during full-scale manufacturing, the parts or products created during prototype tooling remains the same as the final output. These parts can be used for stress testing and impact. The output of the result can help you modify the prototype before heading to the final manufacturing process. Using this process or method of technology can always help in the production period without spending a fortune.

Prototype Tooling Applications:

When talking about prototype tooling, you can always discover a gamut of applications. Due to the creation of innovative processes, these applications will continue to expand. The development of casting cores and shapes is an application of prototype tooling. In sand casting cores and shapes, using SLS application has become a great deal. The process can also be applied when designing molds. It can be either non-metallic and metallic molds via the prototype tooling process. The development of marking stamps with the help of electrodes emanating from EDM remains another excellent application of prototype tooling. It helps in the production f splintering tools and hybrid patterns.