With 3D printers becoming more affordable and hitting the mainstream, manufacturers are asking themselves. Are they ready to join the bandwagon? Before you do, here are the essential facts that you should know about 3D printing.

3D printers are far from the old daisy wheel printer or the dot matrix. It even bears little resemblance to the present photo or document printers as they can only print in two dimensions. These printers are so much more. They print objects in three dimensions and can do it using a variety of materials.

The first 3D printers were bulky machines but now times have changed. You can find them in big-box retailers or online where there are plenty of materials and printers to choose from. Although most of these printers are still in the shop floors or design studios, it can now be found in small workshops and even homes near you.

3D Printing Defined

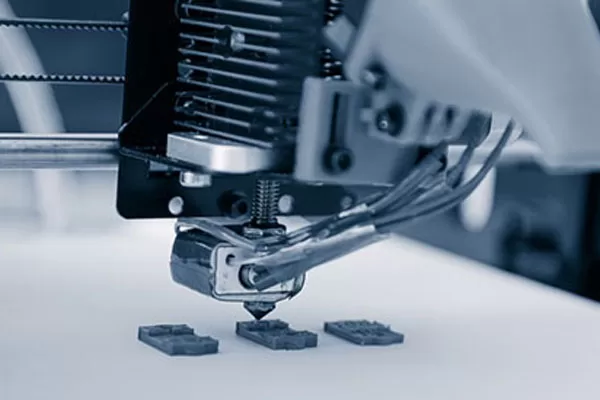

The simplest description of 3D printing is it’s a manufacturing process where the material is put layer by layer to create a three-dimensional object. It belongs to the additive process of manufacturing because the part is made from scratch. In contrast with the subtractive method where the material is drilled, machined off, milled, or cut.

3D printing can use different materials like metal or plastic and techniques as long as it can turn a digital file that has three-dimensional data into physical parts or objects.

3D printing process

Why is 3D Printing Classified as Printing?

If you take a look at the definition of printing, you might have a doubt why it’s even classified as printing. The textbook definition of printing dwells on the production of printed matter, photographs, or publications that are produced through impression with an application of pressure.

Nothing in this definition comes close to what 3D printing is. However, from a technological perspective, it seems that 3D printing goes beyond the traditional definition, where a thin layer of ink is applied. In traditional printing, the height of this ink is so thin that it’s barely noticeable.

What 3D printing does is to extend the height with the multiple layers, thus creating a three-dimensional object, Thus, we can accept that 3D printing can still fit in the definition of printing in an expanded form.

The 3D Printing Technologies

Printing is already a technological advancement and in 3D printing, it applies a different set of technologies. One of them is called fused deposition modeling or FDM. It is also known as fused filament fabrication or FFF.

In this method, the process uses a filament that has polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and another kind of thermoplastic. All these materials are melted and put into the heat extrusion nozzles and expel it in layers.

The first of these printers were introduced in the 1990s by a company called Stratasys in cooperation with IBM. It uses FDM (Stratasys trademarked this name) and most of these printers service schools, consumers, and hobbyists.

Stereolithography is another technology used in 3D printing. In this process, the UV laser is beamed into a vat with UV-sensitive polymer and traces the object on the surface. The beam prints the object in layers based on the instructions of the CAM or CAD file.

Its variation is the use of a digital light projector to print the object. Here, the liquid polymer is exposed to the light from the projector. The light hardens the polymer layer by layer until the part is completed while the remaining liquid material drains off.

There is also multi-jet modeling which uses an inkjet-like 3D printer. It sprays a glue-like, colored binder into successive layers of powder until the object is formed. Among the 3D printing technologies, this is the fastest method and supports printing an object in multiple colors.

New developments in 3D printing introduce modifications like replacing the ink in standard inkjet with other materials aside from ink. An example is in selective laser sintering or SLS which uses different particles like glass, ceramic, metal, or plastic. In the medical field, Titanium is used with Electron Beam Melting or EBM to make medical implants. The same process is applied to making parts of an aircraft.

The materials used in 3D printing may vary depending on the use of the parts or products. It includes metals like aluminum, titanium, stainless steel, and many others, polymers and plastics, composites (plastic with metals or wood), ceramics, glass, plaster, and even food products like chocolate and cheese.

Final Thoughts

We have witnessed the explosion of 3D printing technologies in the last few years. Its trajectory is much like the computers in the 1980s. Although we can see the industries that are benefiting from 3D printing, we may not predict where it can lead to. it may not have the same impact but it has shown great potential in revolutionizing the manufacturing world.