3D printing or additive manufacturing has revolutionized the manufacturing industry. This manufacturing technique has changed the way products are created. It has brought millions of manufacturing jobs and set off a fresh wave of economic growth across several industries.

From manufacturing complex engine parts to dental plants and hearing aids, these are all proof of how different industries have embraced the use of 3D printing. 3D printing has enabled them to make small batches of orders for high-performing and customized parts. Additive manufacturing may be serving several niche markets today, but in the coming years, it will be entering the high-volume circle too.

Since the technology is here to stay, we will explore the impact of 3D printing on the environment in this article.

3D Printing and the Environment

Traditional manufacturing techniques have plenty of negative impacts on the environment. With 3D printing, companies and manufacturers find this method can significantly reduce carbon footprint. Here are the benefits of using a 3D printer in the environment.

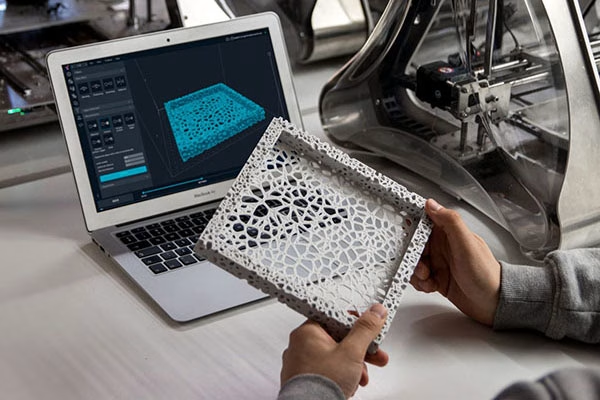

3D printing products

Products are made on demand

Today, the main problem with many companies is they produce more products that can be consumed by the market. It causes a massive inventory of unsold or discontinued products that are a waste of time and money. In the end, they will just fill up the landfills.

It can be avoided by simply using 3D printing during its manufacturing and producing only the quantity needed by the consumers. This saves money and time for both the company and the manufacturer.

Convenience in producing parts for repair

We cannot use the functioning items in our house when it’s broken because we either have to wait for the broken item or find available replacement parts. It will be an additional waste if not fixed.

There are desktop 3D printers that can be used to print these parts and fix these broken items. Accessibility to low-cost 3D printers and the availability of product part CAD files in open sources have this possibility.

In the future, consumers don’t have to contact the manufacturers to ask for replacement parts. They only need to download the files and print them at home. They don’t have to wait for weeks to arrive at their post or get it shipped from overseas.

Less Material Wastage

Every manufacturing company is looking for innovative ways to improve on the area of material waste. Traditional manufacturing methods are heavy on wastes that hit the company’s bottom line.

When 3D printing is used to produce products, it will only use the material needed to create the part. It results in little-to-no material waste. That is part of the reason why many manufacturing businesses are switching to 3D printing not only to save money but to save on waste of materials too.

Massive Savings on Logistics

Consumers are used to the idea of products traveling across the globe to reach them. For example, if a product is made in South Africa it will have to travel a fair distance to reach the UK where it is needed.

When a company incorporates 3D printing into its manufacturing methods, it is possible to get the CAD file and recreate the product using the locally available material. It has a positive impact on the environment and the move will be welcomed by consumers who are looking for ways to save and reduce waste.

Conclusion

3D printing is becoming more accessible now than ever. Over the next decade, we will be seeing the full impact of 3D printers not only in the manufacturing industry but also its benefits to the environment.