Among the aluminum products out there, aluminum extrusion is the most popular. And aluminum extruded products are being used around the world in many innovative applications. That comes as no surprise. Aluminum, for one, is a very versatile material. Its uses know no bounds.

This material is known for its flexibility, strength, durability, and sustainability. As such, you can find aluminum in several end-user sectors like transportation, construction, machinery, electrical, and various consumer products. They are also recyclable, limited toxic emissions, and are easy to process.

Today, aluminum extrusion products are replacing steel in construction and transport. The main reason is because it is lightweight, recyclable, and possesses corrosion resistance.

In construction, 65% of aluminum content is recycled every year. Its usage will most likely expand in doors, windows, panels, ladders, window frames, bridges, and many more.

Aluminum Extrusion Basics

When we think about the material being extruded, think of your favorite toy, Play-Doh. Just like the clay being pushed into a mold, the heated aluminum material is pushed through a hole to come up with a long product with a uniform cross-section.

However, extruding aluminum is more complex, but you’ve got the same idea. A billet of aluminum is heated and loaded into an aluminum extrusion press. A ram is used to apply pressure on the billet and forces it to flow into the small opening at the end of the chamber. The opening will have the profile that the aluminum takes on.

Once the extruded material comes out of the die, it is moved on to the lead-out table. There it is cut to the desired length. It is then transferred into the stretching table where it will be cut into the desired length ready for shipping.

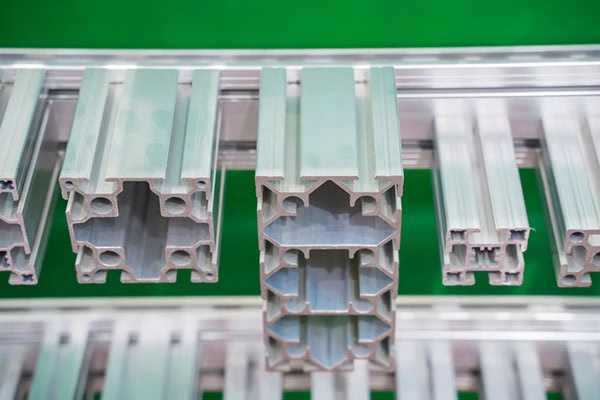

Aluminum Extrusion can make a variety of profiles and it can be classified into solid, hollow, or semi-hollow. Some of the shapes under solid extrusion are square, rectangle, or round. Most hollows are tubes, squares, rounds, or any shape and close space. The semi-hollow types form a C-shape with a small opening in its profile.

Aluminum extrusion design

Common Applications of Extruded Aluminum

Here are the top applications where extruded aluminum is used.

- Construction and Architecture: In this sector, the application of extruded aluminum ranges from railings and balustrades to canopies. It is also used in suspended ceilings and walls. Many ladders in construction are made from aluminum extrusion.

- Display Equipment: Every stand in exhibits is made from aluminum extruded materials. It is because the piece is designed to interlock, facilitating easy assembly. The material is lightweight, so it is easy to move around. Other application includes point-of-sale displays, frames, and cabinets.

- Electrical System: Another application of aluminum extruded material is in busbars and other electrical components. LED fixtures can have thermal management challenges, but modified aluminum with fins can serve as an excellent heat exchanger. It does not weigh much when mounted too. Aluminum is also used in the installation of solar panels.

- Industrial: Most of the structures in factories and manufacturing plants are made with aluminum extruded materials. They are used in workbenches, tables, and carts. This material is easy to cut yet durable and has good value for money.

- Transportation: As mentioned earlier, weight and corrosion are major issues in transportation. Aerospace is a dead giveaway, but for land transportation, the trailer is one example. You need a lightweight material to reduce the pressure.

Final Thoughts

If you think about aluminum fabrications, you can see them anywhere. Take a hard look at whether it is made through aluminum extrusions. Chances are you will many of them. It is an extraordinarily versatile material.