With so many articles online about CNC machining, everybody is quite familiar with the process, its domain, and its benefits. For the benefit of those who are new to the CNC terms, I will give you a quick summary of it later.

The progress in computing technology and its adaptations in many industries has led to the popularity of CNC machining as a manufacturing method. Today, this process is widely used across the board for manufacturing and fabricating applications. It is a significant part of modern machining and it’s not going away anytime soon.

What is CNC Machining?

Computer numerical control connects the machine and tools to a unique digital control system. There are two parts in a CNC machine, the software, and the hardware. In running the CNC machine, the operator controls the software that operates the machine and tools. He or she also creates the programs to make the part.

The software dictates the instruction on how the machine should work to create the part. In turn, the machine will read the program and direct the tools on how to behave. It is a simple process that is faster and error-free.

The various tools of CNC machines can be controlled are:

- Grinders

- Routers

- Mills

- Lathes

In traditional machining, the operator has to directly control all the movement of the machine tools. It is all in the hands of the operator even when he has to move the device. He also has the decision which feeds, where and when it should stop. To have better precision, the operator uses gauges and rulers that are integrated into the controls.

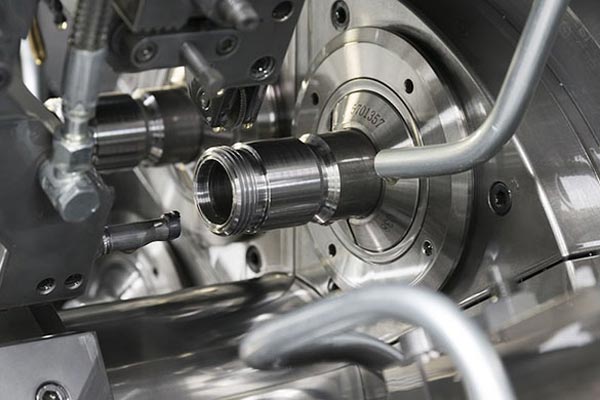

CNC machining

The Advantages of CNC Machining vs. Traditional Machining

Here are the reasons why you should consider CNC machining as your manufacturing process for your next project.

It Requires Less Manpower to Operate the Machine

Conventional machining needs additional investment in hiring experts and skilled workforce to operate the machine. There is also an additional cost on machine maintenance and repairs. All these are added expenses to your operating costs.

CNC machining streamlines machine operation, and therefore, cuts down the additional costs on labor as there are fewer operators involved. These few operators can deliver results without compromising the quantity or quality. That means, manufacturers can achieve their target productivity costs with little investment.

Another factor why the CNC machine is more beneficial is the operator’s safety from sharp tools. With the setup of the machines, the operator is working on the computer behind the glass. He does not come close to the machine or any of the materials.

It Does Not Need Comprehensive Skills or Experience

Traditional machines not only need additional operators to run, but these operators also need to train on how to operate them. Some may also need years of experience before they can work on them.

Although experience is also good in operating CNC machines, in some cases it is not as compulsory as in traditional machining. That’s because CNC machining has made the production process simpler and that rules out the possibility of human error.

These machines can have a maximum output with minimal participation of the operator. That means it wins over traditional machining in terms of output and risks of committing errors.

It Can Easily Replicate Products with High Precision

It’s great to use conventional machining when you are customizing a part or product. However, when the demands are high and you need to produce the same parts over again, it will not be able to cope up. This is where CNC machining comes in.

CNC machines can make the same part with high precision and the same quality no matter how many. Traditional machining cannot live up to these expectations because even with a skilled operator, he or she can never make the same piece without tiny variation.

It Can Boost Your Production Options

Since CNC machines are easy to operate and require minimal labor costs, it can improve your production processes. The software allows product designers to create parts with complex geometries that are nearly impossible to create using conventional machines.

It is also easy to update and it can add to the functionality of the products. With conventional machining, it will not be easy to do.

You Don’t Need Prototypes With CNC Machines

The CNC technology is a convenient system where you don’t have to make a prototype before manufacturing the part. Prototyping can add cost and it is a very time-consuming process. Thanks to the CNC software, you can put the idea directly into the file before cutting them.

The software cuts down the processing time because it eliminates the revisions and reworks involved in prototyping. This is not possible with conventional machinery.

Final Thoughts

With the many advantages that CNC machining offers, these machines are used in different industries including industrial, manufacturing, defense, aerospace, and medical industries. Don’t crowd your shop floor with conventional machines. Consider CNC machines for all your machining needs.