Standard aluminum extrusion don’t fulfill the desires of each industry or application. On the other hand, with custom aluminum expulsions, it’s conceivable to completely customize a wrapped-up item and meet the strictest details. Custom aluminum extrusion enable creators and engineers to form the items, devices, and materials that will fulfill particular necessities whereas giving the most extreme long-term execution. The key, of course, is to guarantee the utilization of high-quality items. When it comes to aluminum expulsion providers, the critical thing for clients is to select a company that centers on quality and accuracy. In expansion, there ought to be a built-in capacity to provide the wrapped up merchandise around the world and with streamlined coordination.

High Precision for Aluminum Extrusion:

One unequivocal advantage of aluminum when compared to other items is its capacity for near resistance. In truth, a great expulsion provider can make all sorts of complex shapes and sizes utilizing advanced techniques. For a few clients, tall accuracy components are basic, and custom aluminum extrusion can suit those prerequisites with shape and estimate and wrap up to suit. The huge advantage of customized expulsions is the capacity to fulfill exact item details that are characterized by each client.

Performance for Aluminum Extrusion:

Items made of aluminum are non-magnetic and are amazing conductors of power and warmth. As for aluminum expulsion items, the wrapped-up expulsions are solid and solid, making them perfect for a tremendous extend of industry applications. And since aluminum itself is anti-corrosive, the wrapped-up item is an amazing choice for any open-air application much superior to conventional steel. Designers, for illustration, may require an item that fulfills a particular industry standard.

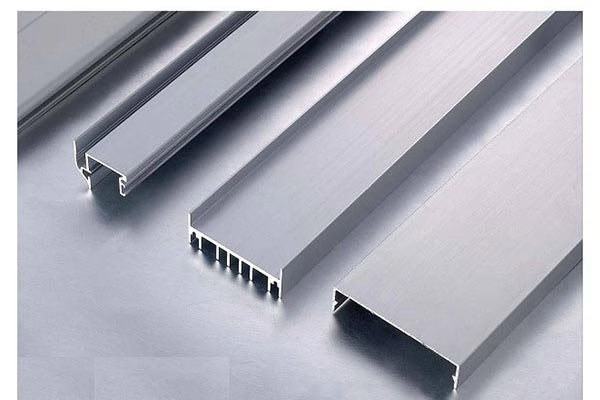

Aluminum extrusion parts

Cost-Effectiveness of Aluminum Extrusion:

Anything the working budget, aluminum extrusion can give the foremost cost-effective arrangements compared to other fabric creations. Aluminum is particularly cost-effective since it’s a straightforward fabric to work with, in this manner lessening the taken toll of tooling significantly. As well, labor costs are less with aluminum, particularly considering the extremely tall fetched of a few generation forms. Moreover, within the angling industry, there may be a requirement for a special, non-standard shape.

Finish Options for Aluminum Extrusion:

Whereas aluminum expulsion providers can make any shape, measure, or setup, extra customization is conceivable when it comes to wrapping up choices. Custom coating arrangements are essentially boundless and generally simple to join right at the creation arrange. Conceivable coatings and wraps up may incorporate conventional portray, powder coating, and anodizing which upgrades and secures the wrapped up surface. Contact OD Metals specifically to memorize approximately all of our finish options. And at long last, within the auto industry, aluminum parts require temperature steadiness and erosion resistance.

A Green Metal for Aluminum Extrusion:

Not to be downplayed, aluminum could be a metal that can be reused boundlessly without any debasement in its physical properties. For end-users who are arranged to utilize reused aluminum, the carbon impression of the expelled parts is essentially decreased. The truth is, reused aluminum requires less than 10% of the vitality compared to creating essential aluminum.