3D printing is no longer stuff of legends, as it is now available for everybody’s use. Since most of the decision-makers in larger manufacturing companies believe in the potential of 3D printing, we are seeing a continuous rise in the use of 3D printing.

Aside from delivering cost savings, the improvement in the technology has answered some of the limitations that hinder its growth in the past. Many bigwigs in the industry are convinced of the viability of additive manufacturing and how it can impact the company’s bottom line.

3D Printing’s Role as a Complementary Technique

When 3D printing was first conceived, it was not meant to replace the traditional manufacturing technique. It was meant to be a complementary technology that can work alongside other manufacturing methods to improve its efficiency in every step of the process.

For example, the availability of print-on-demand for spare parts provides solutions in areas that have limited access to the supply network. Another way where 3D printing helps is in customization, where the demand for personalized items is high.

These are just manifestations of how 3D printing can help companies drive the transport and warehousing cost down, optimize the processes, and slash production time. The most significant of which is accessibility.

Although it did not transform the supply chain completely, the improvements in the hardware, software, and materials used have led small organizations to consider 3D printing as part of their blended production model with little investment.

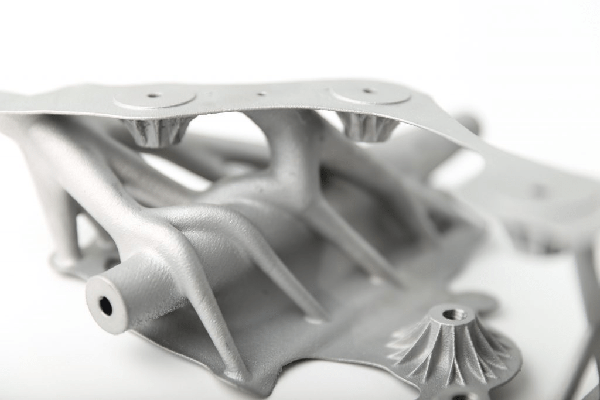

3D printing parts

Improving Uptime and Time to Market

One of the critical items in the Key Performance Indicator (KPI) of a manufacturing company is minimizing production downtime. By maintaining high uptime, they can reduce costs, shorten the time to market while keeping a strong customer relationship. Although companies have managed their processes to achieve the KPIs, a simple equipment breakdown can jeopardize the uptime KPI.

As a solution, companies have integrated 3D printing into its operation. It unleashed a wide range of benefits, such as being able to locally print difficult-to-find spare parts. Sourcing, often from overseas, can cause longer downtime and expense. Having a 3D printer allows them to save time and money. It also shows the 3D-printed plastic parts are as good as metal parts.

Enhancing Operations

Another benefit of 3D printing is its ability to bring complicated designs to life and quickly make alterations and revisions without much impact on the costs and lead times. This applies to custom tools that can be printed overnight and tested on the production line the next day. The user’s feedback is critical for incorporation in consecutive design iterations.

Health and Safety Benefits

Another fiscal benefit of 3D printing is on health and safety. One example is how 3D printed tools are easier to handle compared to traditionally crafted metal tools. 3D printed parts are often lightweight and address the ergonomic aspects. The iterative approach to 3D printing means that organizations can continuously improve the usability of the product. As a result, it enhances the employee experience.

And because you can share 3D printing files online, it is easy for multinational companies to expand their innovations across all locations. They can spread the solution online and accelerate its application. There is no need to physically transport the parts, eliminating the issues of poor logistics.

Conclusion

The fiscal benefits of 3D printing could not be ignored. These are the reasons why businesses are considering the role of 3D printing in a blended manufacturing process. A business can easily transform a comparatively small investment into a significant business benefit.