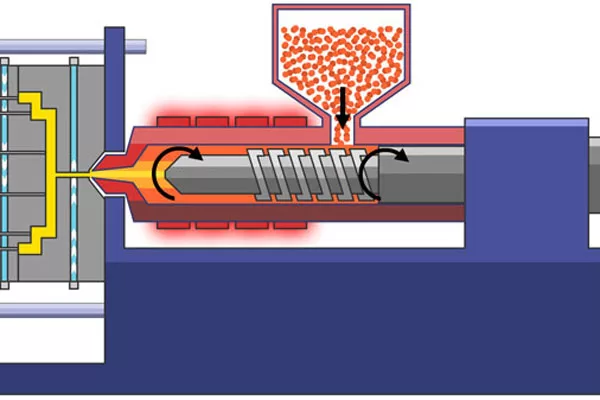

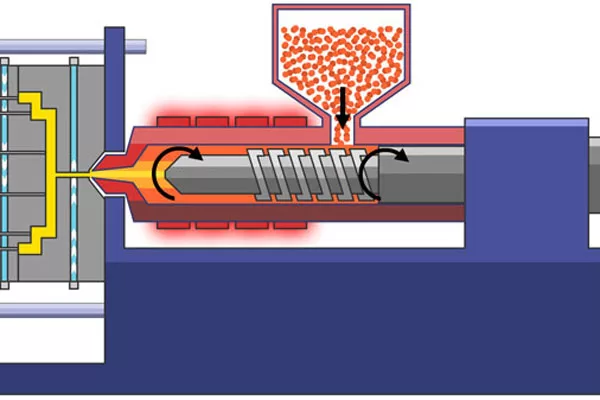

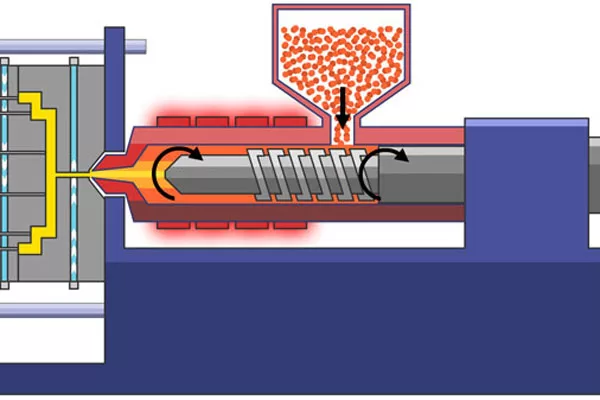

by Nice Rapid | Oct 19, 2020 | Plastic Injection Molding

When it comes to the design of the final product using plastic injection molding, the main objective is to always create a near-perfect design that works at a minimal cost. To achieve this goal, there are always different steps involved. Due to technological...

by Nice Rapid | Oct 15, 2020 | Liquid Silicone Rubber Molding

The production sectors have witnessed a significant shift in recent years, companies now can create complex and intricate geometries partly thanks to liquid silicone rubber molding. Liquid silicones rubber molding has been around since the 1970s and has become the...

by Nice Rapid | Oct 12, 2020 | Rapid Tooling

A critical step in manufacturing is tooling. This step involves producing the tools that will help create the product, and it includes cutting equipment, molds, jigs, dies, other custom parts. Manufacturers have lots of options in completing this process, and they...

by Nice Rapid | Oct 9, 2020 | Liquid Silicone Rubber Molding

Material performance is significant in any application, even more so when the lives and health are at stake. One of the particular challenges in finding a material that is viable for medical application is tough enough to withstand heat, chemical exposure, and...

by Nice Rapid | Oct 4, 2020 | Low Volume Manufacturing

The use and application of low-volume manufacturing have been on the rise in recent years? But what is low-volume manufacturing by definition? They are no clear and concise definition of low-volume production as its subjective and its definition depends on the type of...