There are several things revolutionized nowadays in the industry. Everyone is looking for the best way to reduce the labor efforts to make the way perfect to save a good amount of money during production. Those who are seeking the best way of making the process of cutting or drilling the materials CNC milling is one of the best ways to do. CNC milling is helpful to save time or money both with the way of precise cutting or processing.

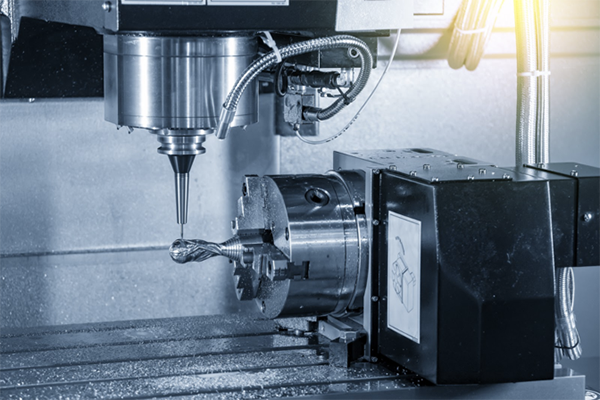

CNC milling tools have used to perform machining processes. CNC milling is used rotary cutter to evacuate the unnecessary material from the work piece. These days, it can be proved as the best industrial solution due to a different source of shapes and sizes that milling can do.

The cylindrical cutter in the milling machine has moved on multiple areas to create several shapes, holes, or slots. Mostly, these machines have used on a 3 to 5 axis that will work with advanced tools to perform sophisticated machining.

On the other hand, CNC milling machines are assembled with vertical or horizontal machining centers. It has advanced features to precisely cut the components of composite materials or plastics. Moreover, cut the metal accurately. It has equipped with several features such as tool changer, magazine and coolant systems or many more.

4 axis CNC milling

Which industries have the most used CNC milling?

Several Industries need CNC milling machines. Moreover, these industries are completely useless without CNC milling machines.

- Prototype or custom design

- Commercial

- Maintenance

- Electronic

- Security or Technology

- Automotive or transportation

Is CNC milling machine used for products or industries?

CNC milling can work on geometric tolerances for several aspects. It has features to measure the accurate position, profile or diameter of the product. It has considered the best affordable pulling cost or can create a huge range of complex parts. Nowadays, CNC milling can be the best solution for several projects from prototype to complete the fabrication of different components.

Is it produced cost-effective designs?

Would you want to cost-effective designs? Yes, it would be possible to get cost-effective designs by CNC milling machines. Nowadays, investment in CNC milling can be a well-known factor to boost the production rate. Moreover, it’s a great return on investment when you find that it saves a huge amount of material with features of accurate cutting.

Not only CNC milling has used to make the components of different structures, but it also uses to alter things that make work effortless. For example, aerospace or transportation requires a different kind of components. All these components are useful to assemble the machinery and that is a greater and technology for the society. To bring several changes or add on various features in the production, different kind of components are required that is taken by CNC milling. If you still have any doubts, you can get more information on CNC milling or know about the benefits of using the technology for several projects.