Profile Precision Extrusions are used in the manufacture of a wide range of custom aluminum extrusions, especially for the medical device industry. It’s mainly used in a wide variety of functionalities like research equipment, hospital room equipment, and furnishings.

One of the major benefits of aluminum extrusion is the fact that it provides a certain degree of design flexibility. The flexibility allows for the manufacture of complex medical devices that would have otherwise impossible using other production techniques.

One thing about medical devices is that they cannot be produced using traditional or conventional metals. What this essentially means as a manufacturer you’ll be able to spend limited time when it comes to manufacturing which will have a direct effect on your finances making the whole production process economical.

Bio-compatibility and Availability

Extruded aluminum components can be found in a wide variety of diagnostic and surgical devices. Aluminum tubes and multi-hollow shapes are mostly found in stethoscopes, trocars including other disposable tools. I know some didn’t know about this fact and they are quite surprised.

Additionally, to the use and availability of extruded aluminum for medical devices, alloys like 6061, 6063, and 3003 are biocompatible. Aluminum coatings such as anodize or chem-film, are RoHS compliant and biocompatible.

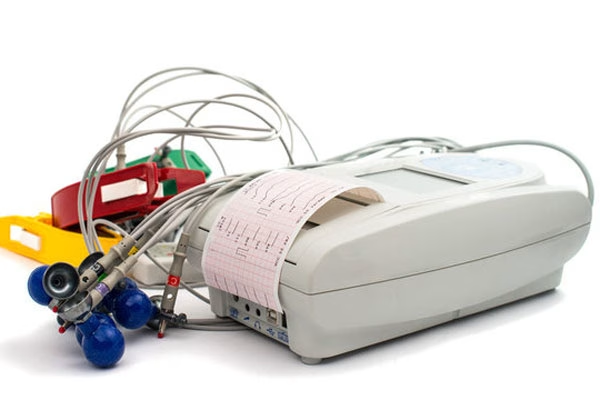

ECG machines

New Medical Device Project Benefits

For modern medical projects and devices, speed, quality, and cost are very essential. With aluminum metal, you can make a single extruded profile which in the long run removes all the joining costs.

Not only is aluminum material lighter compared to steel, but it also gets stronger as temperatures drop whereasplastics and steel come up a little bit short. At Nice Rapid, we can completely design review, feedback, and formal quotes in just under 24 hours.

Another main advantage of extrusion tooling is the entire procedure is inexpensive as well as having shorter lead times. In most instances the tooling can be built within just two weeks, how amazing is that.

Tooling cost when it comes to making all medical products is cheaper and cost-effective compared to stamping or injection molding. Most multi-nationals and big corporations such as 3M Healthcare, Smith & Nephew, and Johnson & Johnson use aluminum extrusion technique when it comes to the making of medical devices and equipment’s like for example Aluminum ear tubes are very important components of the stethoscopes.

Aluminum tubing is used in a wide variety of applications especially in disposable surgical tools like circular, laparoscopic staplers, trocars instruments. Extruded aluminum electrodes are especially used in electroporation cuvettes specifically used in DNA research.

There is one myth that we need to talk about aluminum that states that exposure to aluminum results in Alzheimer’s Disease. The truth of the matter is aluminum has not been known to cause Alzheimer’s according to the World Health Organization and The Alzheimer’s Association.

In just over 30 years, Profile Precision Extrusions has been mainly used in the creation of aluminum tubing and extruded aluminum shapes for the medical device, industrial markets, and aerospace.