by Nice Rapid | Mar 26, 2025 | Compression Molding

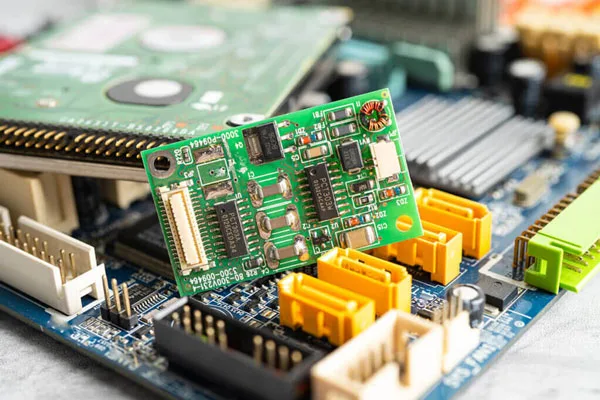

Compression molding is a manufacturing process in which raw material is compressed in a mold under high temperature and pressure. It is perfect for manufacturing parts that require a very high-performance level, as well as intricate shapes and narrow clearances. They...

by Nice Rapid | Mar 12, 2025 | Compression Molding

The manufacturing world is shifting toward greener alternatives, and compression molding with natural fibers leads to this change. You can create strong, lightweight composites while reducing environmental impact. Let’s explore how natural fibers are reshaping...

by Nice Rapid | Feb 28, 2025 | Compression Molding

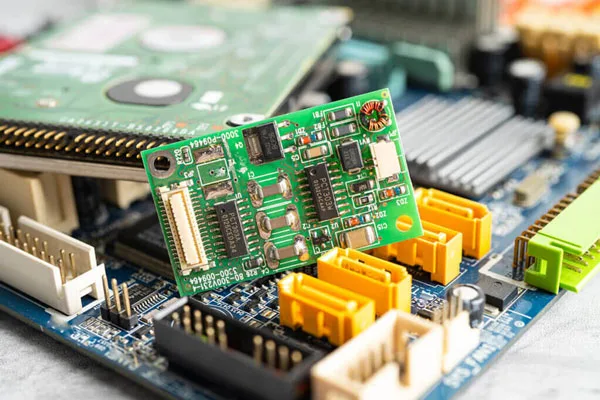

In the world of manufacturing, where innovation and efficiency reign supreme, finding ways to create durable, high-quality components while keeping costs in check is an ongoing quest. Compression molding has emerged as a true champion in this endeavor, proving itself...

by Nice Rapid | Jan 20, 2025 | Compression Molding

Compression molding has been around for a while, but it’s experiencing a resurgence in popularity thanks to the rise of composite materials. These advanced materials are changing the game in industries like aerospace, automotive, and renewable energy, demanding...

by Nice Rapid | Jan 6, 2025 | Compression Molding

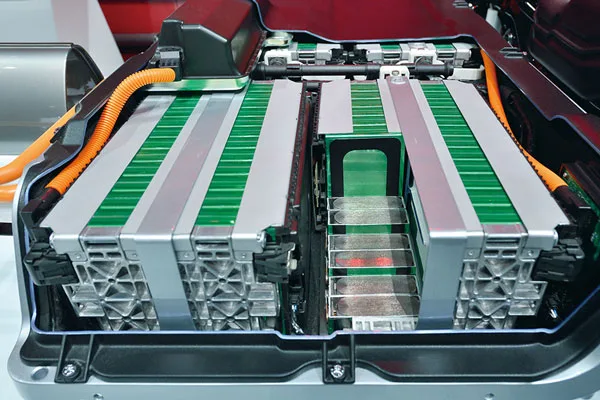

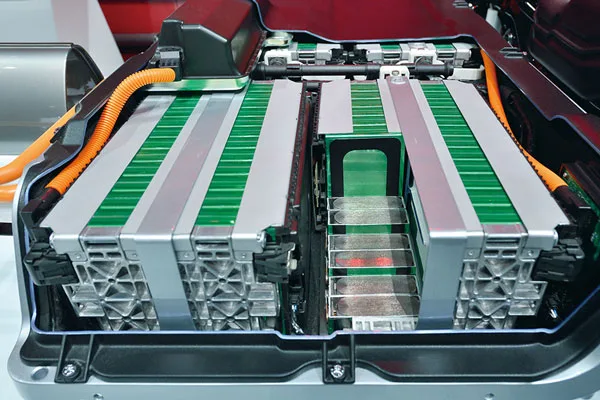

The electric vehicle (EV) industry is rapidly expanding, and with it, the demand for high-performance batteries. At the heart of this growth is compression molding, a manufacturing process that plays a critical role in producing key components for these batteries,...

by Nice Rapid | Oct 30, 2024 | Compression Molding

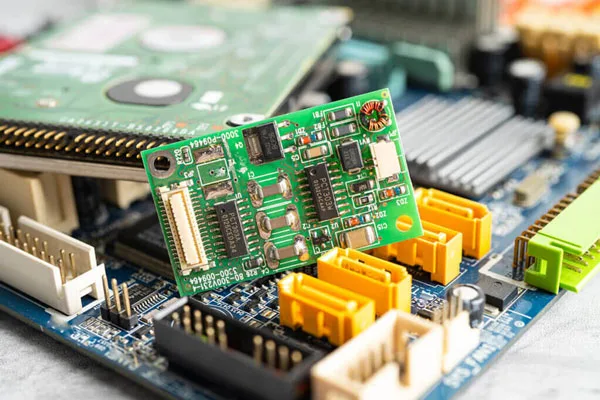

Compression molding, a time-tested manufacturing process, involves placing a preheated material into a heated mold cavity and applying pressure to form it into the desired shape. While it might seem like an older technology, compression molding continues to find...