by Nice Rapid | Apr 6, 2021 | Plastic Injection Molding

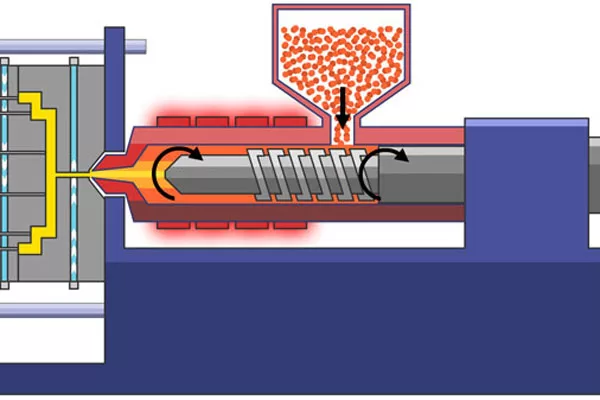

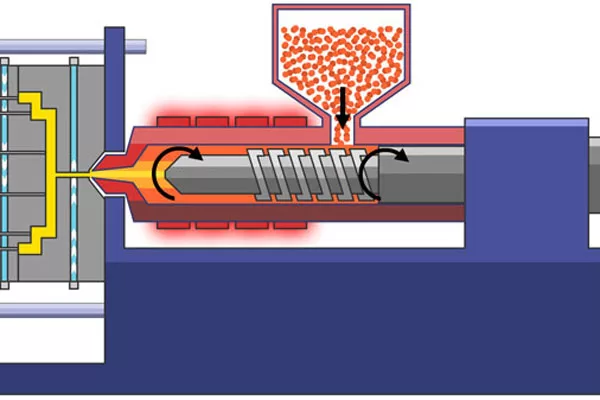

Infusion molding requires an extraordinary bargain of the forthright plan and designing to create nitty-gritty tooling or molds. Created from stainless steel or aluminum, split-die molds are infused with liquid fluid polymers at tall temperatures beneath the...

by Nice Rapid | Mar 5, 2021 | Plastic Injection Molding

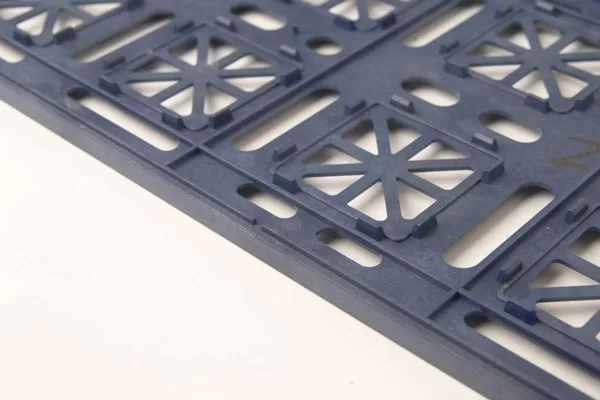

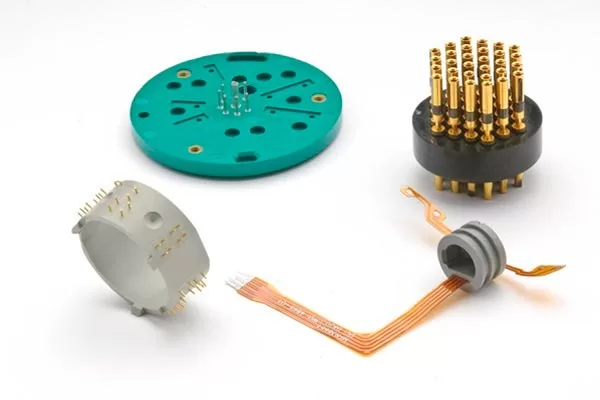

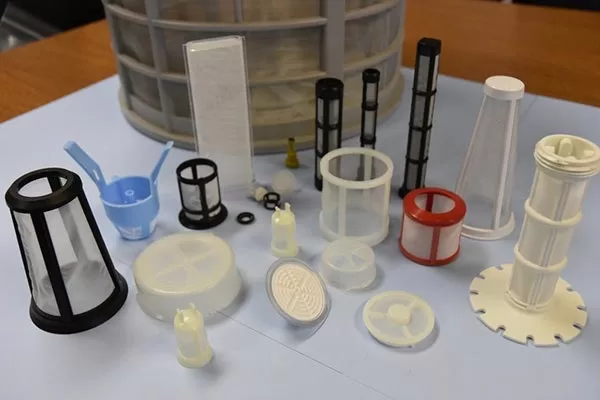

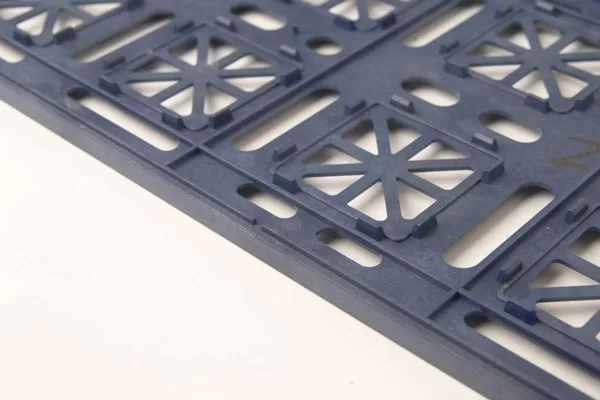

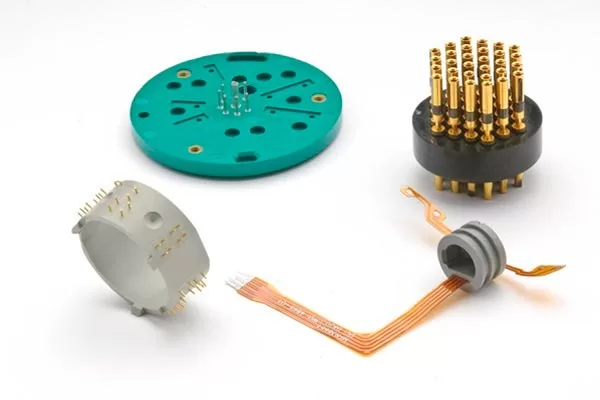

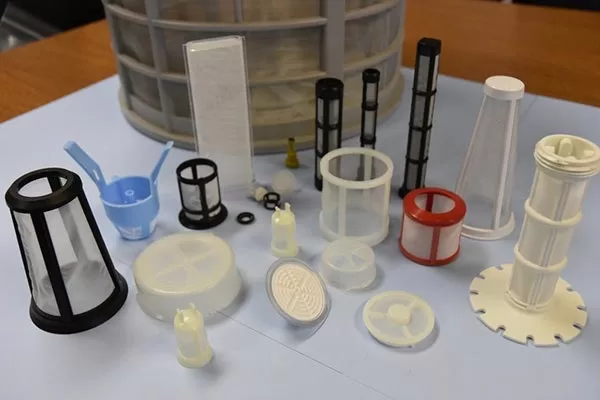

The injection molding process is highly versatile and can make a wide range of parts for different applications. Some of the parts that use injection molding applications include packaging, bottle caps, wire spools, automotive dashboards, combs, and many other plastic...

by Nice Rapid | Feb 7, 2021 | Plastic Injection Molding

Here is a fan fact, most of the products that we use in our everyday lives are made from injection molding. Have you ever sat and wondered why is this so? Well, the answer is quite simple, injection molding is one of the most versatile techniques when it comes to the...

by Nice Rapid | Jan 27, 2021 | Plastic Injection Molding

The day and age of the internet have truly changed everything, well it may sound like a cliche but it’s true when it comes to the manufacturing world. The changing trends in technology and the internet has significantly improved the way manufacturing is done....

by Nice Rapid | Oct 19, 2020 | Plastic Injection Molding

When it comes to the design of the final product using plastic injection molding, the main objective is to always create a near-perfect design that works at a minimal cost. To achieve this goal, there are always different steps involved. Due to technological...

by Nice Rapid | Sep 17, 2020 | Plastic Injection Molding

Let’s just take a brief moment and appreciate how one plastic injection mold has transformed the whole manufacturing process making everything seamless and easier compared to traditional methods. Well even though plastic injection molding comes with a lot of...