by Nice Rapid | May 2, 2024 | Plastic Injection Molding

In the realm of modern manufacturing, few processes have revolutionized the production of plastic parts as significantly as injection molding. Injection molding stands as a cornerstone of mass production, offering unmatched precision, efficiency, and versatility. This...

by Nice Rapid | Apr 7, 2024 | Plastic Injection Molding

In a world where every footprint leaves a mark, manufacturing must evolve, and injection molding steps into the arena as a game-changing process. The harmonious blend of efficiency and sustainability makes this technological marvel stand out. Picture this: plastic...

by Nice Rapid | Mar 20, 2024 | Plastic Injection Molding

Plastic components feature excellent flexibility in production processes, making them a popular choice in many industries. Manufacturers can create components that meet clients’ exact requirements and specifications, benefiting many industries. However, choosing...

by Nice Rapid | Mar 11, 2024 | Plastic Injection Molding

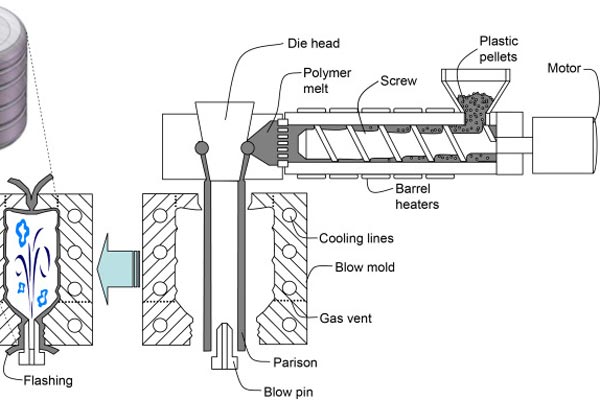

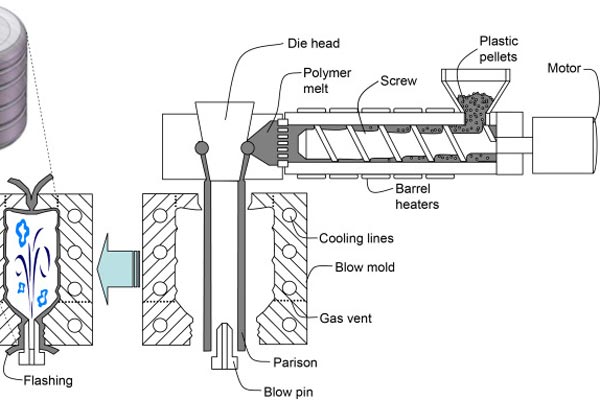

The process of blow molding involves the formation of plastic products using thermoplastics. These products have a hollow design and are formed through the heating and inflation of plastic tubes known as “preforms” or “parison.” The...

by Nice Rapid | Dec 29, 2023 | Plastic Injection Molding

Injection and over-molding processes are commonly used in many industries for the production of plastic and composite components. The rise of the smartphone in the last two decades saw hundreds of manufacturers design protective casing for these devices. These...

by Nice Rapid | Oct 6, 2023 | Plastic Injection Molding

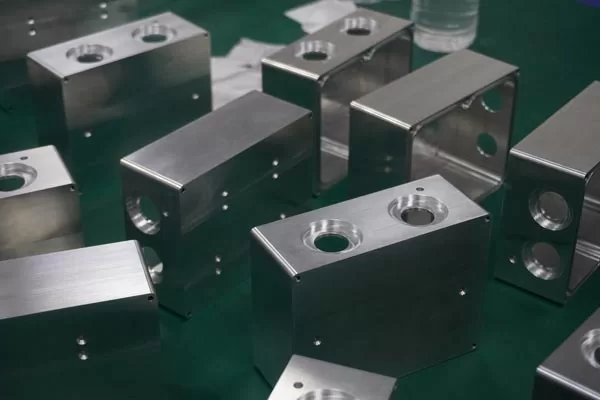

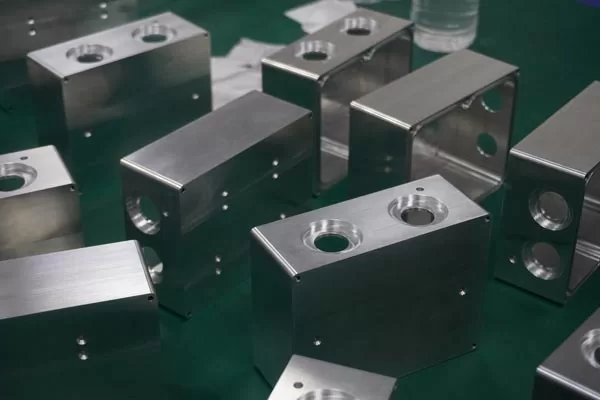

Metal injection molding (MIM) is a rapid prototyping and production process suited to high-volume production applications with intricate components or complex shapes. It’s one of the most frequently used manufacturing processes in modern prototyping and mass...