by Nice Rapid | Oct 30, 2020 | Rapid Tooling

When dealing with rapid tooling, there is a lot of information and mixed terms that can get lost in translation. A lot of clients, plus some engineers and designers lack a clear idea with regards to the processes and procedures of rapid tooling and those of rapid...

by Nice Rapid | Oct 26, 2020 | Rapid Tooling

We are at a point where the economic power play of the world has changed, a lot of firms and companies have come to the realization that shipping in manufactured products is quite easy and simple compared to assembling the same products in their plants in different...

by Nice Rapid | Oct 12, 2020 | Rapid Tooling

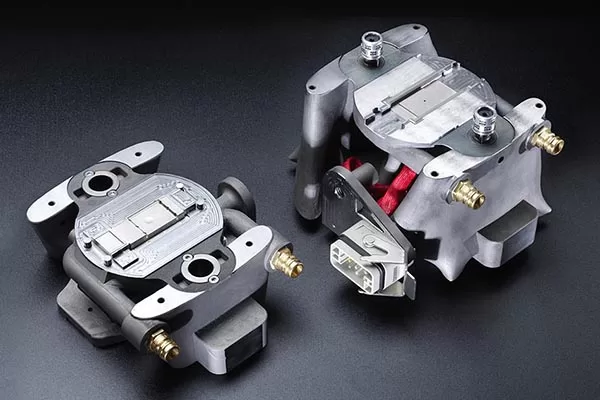

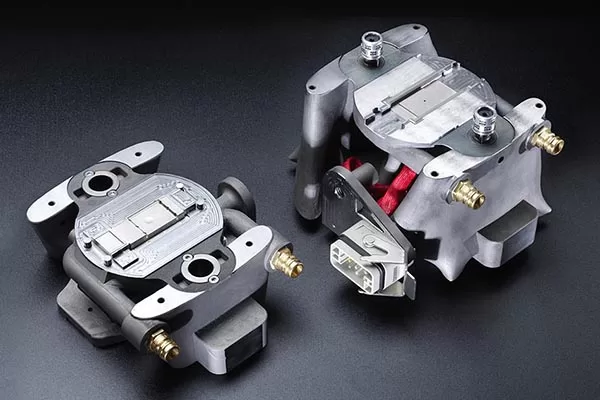

A critical step in manufacturing is tooling. This step involves producing the tools that will help create the product, and it includes cutting equipment, molds, jigs, dies, other custom parts. Manufacturers have lots of options in completing this process, and they...

by Nice Rapid | Sep 11, 2020 | Rapid Tooling

Rapid tooling is categorized into two – Indirect and Direct approaches. The indirect category involves the use of RP master patterns in creating a mold. The direct, on the other hand, use the RP machine in building the core and cavity mold inserts. The increasing need...

by Nice Rapid | Aug 17, 2020 | Rapid Tooling

Tools or more commonly known as dies are needed in every manufacturing process. It has become significant that the annual turnout for the tooling industry is close to 60 billion dollars. In the past, the tool-making industry was dominated by Western economies like the...

by Nice Rapid | Jul 13, 2020 | Rapid Tooling

There are two broad, rapid tooling categories. One involves approaches indirectly making use of quick tooling master techniques for producing a mold. The other uses an approach directly where the machine of rapid tooling creates the real core and cavity mold insert....