Liquid silicone rubber (LSR) is a flexible material used for various things, from medical devices to consumer goods. As such, it’s important that companies looking to use LSR find a reliable and experienced manufacturer who can help them achieve the desired results. In this blog, we will cover key points when selecting a liquid silicone rubber manufacturer.

Choosing an Experienced LSR Manufacturer

Make sure the liquid silicone rubber (LSR) manufacturer you choose has a lot of experience in the field before you choose them. This is because an experienced manufacturer will be truly knowledgeable about the diverse types of LSR and how to use them to suit your project best.

Additionally, a manufacturer with a lot of experience in LSR production will have access to the latest technologies and methods to help them create the best possible product. Also, the manufacturer will know a lot about how things are made, which will help them finish projects quickly and well. Ultimately, an LSR manufacturer with a lot of experience can give you the best materials and work.

Assessing Production Capabilities

Once you’ve found a few possible manufacturers, it’s important to figure out how well they can make your product. This includes looking at the kinds of molding processes they offer, like injection molding and compression molding, and their ability to make products in both small and enormous quantities. It is also important to ask about their lead times and how they ensure that their products are of the highest quality. You can make a better decision by asking about their quality assurance processes and certifications.

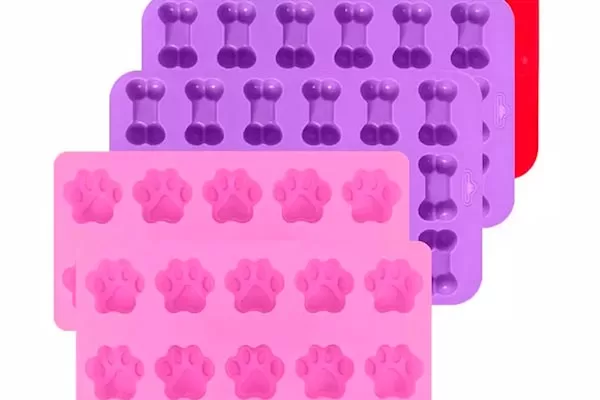

Puppy paw and bone non-stick baking molds

Looking into Their Reputation

When selecting a liquid silicone rubber manufacturer, it’s essential to investigate its reputation. Start by reading customer reviews and talking to other industry professionals to better understand the manufacturer’s record of accomplishment. Doing your research is key when making this kind of crucial decision.

It’s also a clever idea to ask for references from the manufacturer so you can speak directly to their previous clients and gain insight into the quality of their products and services. This can help you determine if they have a history of delivering high-quality results on time.

You can also find the best partner for your needs by doing a competitive analysis of other manufacturers in the same space. By finding out about a potential partner’s reputation, you can make sure they will give you the results you want.

Examining their pricing model

Finally, it’s important to assess the manufacturer’s pricing model. Most liquid silicone rubber manufacturers have a set price per pound or kilogram, but it’s important to understand exactly what’s included in the price. Does the cost include tooling and setup costs? Are there any additional fees for changes or rush orders? If you answer these questions, you can determine if the manufacturer fits your budget.

Conclusion

Finding the right liquid silicone rubber manufacturer for your project can be hard. But you can make sure you choose the best partner for your project by looking at their experience, production skills, reputation, and pricing model. Also, remember to ask the manufacturer what they can do with silicone molding. This will help you ensure that the final product is what you want.