3D Printing can be a great advantage for your business. It can speed up the design-to-market process, making you a true market leader in your industry. However, just like any other manufacturing process, it should be used properly.

When done right, 3D printing can be an asset as it can help you bring down costs, optimize your production process, and build better products. You can use 3D printing not only for prototyping but also for producing final parts for the market.

The question is: How do we know if 3D printing is appropriate to use or not? These ten tips will help you figure them out.

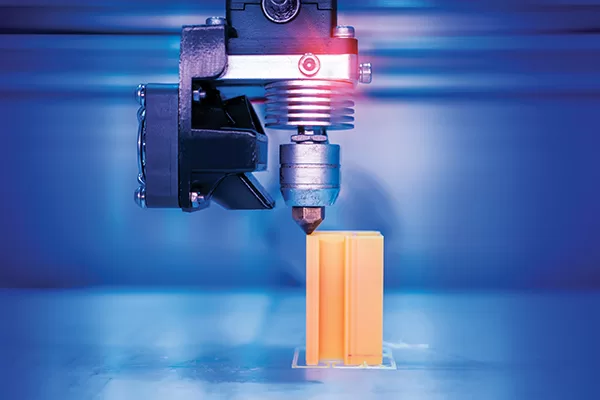

3D printing machines

Guidelines on Implementing 3D Printing

Here are the best tips we can give you on how to identify 3D printing opportunities for your business.

1. Analyze which part of the design will take much of your time

In producing a part, the timeline is the most significant factor in making the decision. 3D printing can help speed up the production process. It can also produce molds for parts that slow down the production process.

2. Configure the manufacturing process for more efficiency

In running a business, efficiency matters, and configuring the production line to maximize productivity should be part of the plan. This optimization may be costly and takes longer. Fortunately, 3D printing can help implement iterations.

3. Evaluate the part that can be more expensive to produce

Part of your optimization is cost. You can change the manufacturing process that you are using to cost less. Why not use 3D printing instead since it will be cheaper.

4. Revisit the design to know which part is causing the bottleneck

In manufacturing a part, you are bound to meet some constraints. When you start using 3D printing, you can free yourself from some of these bottlenecks.

5. Combining CNC and 3D printing to optimize the workflow

When you adopt 3D printing as your manufacturing technique, it does not mean that you have to stop using your other manufacturing processes. You can use 3D printing for low-volume, complex parts. But for simple and large quantities, CNC will do. By combining both, you can have an agile workflow.

6. Make your enclosures with 3D printing

This manufacturing process is perfect for producing enclosures. Manufacturing these parts is easy and cheaper too.

7. Analyzing your needs during part assembly

Another way to take advantage of the benefits of 3D printing is how you can integrate the process directly into the assembly of your part.

8. Customize the fixtures in the most cost-efficient way

3D printing can produce fixtures like tooling, welding and assembly fixtures, and many more. Doing them with a subtractive manufacturing process can be costly until 3D printing makes it all affordable.

9. Manufacturing parts to make the part lightweight

Weight is a requirement in some products, and to make the part lighter, use 3D printing. There are several design tricks that you can employ to achieve this, and 3D printing is the right technique to execute them.

10. Creating replacement parts for maintenance

Your machines can experience wear and tear. Replacing these broken parts can be time-consuming. 3D printing can create these replacement parts faster, creating a lesser impact on your workflow.

Conclusion

You can use these tips to help you implement 3D printing in your manufacturing process. But if you need more information, you can contact an expert to help you figure it out.