The use of additive manufacturing or 3D printing has gone beyond prototyping and rapid tooling. Aside from creating trinkets and toys, it has moved to big companies for industrial production. 3D printing is now on the mainstream.

It has broken the limits of traditional manufacturing techniques by changing the way it creates or supports the production of parts. The key to maximizing the capabilities of 3D printing is knowing how it can deliver maximum efficiency and improve its performance. By unlocking its potential, you will find many financial advantages.

Reduced Production Cost

Many people are afraid to try 3D printing because it is expensive. This high cost is related to the initial investment in the machine and not on production. The truth you can save on production costs by using 3D printing in the long term.

The machine cost depends on the size of the 3D printer. With the advancement in this technique, you can now have desktop 3D printers that work as a laptop. Of course, you have to spend more on industrial 3D printers but they can print complex objects in a single step. Thereby, resulting in greater efficiency and productivity.

3D printing does not need operators, hence, reduced labor costs. Aside from this advantage, it does not need further post-processing. Compared with traditional manufacturing, you don’t have to hire highly skilled operators for your production run.

You can also save on cost when you use 3D printing for your low-volume production. Compared with traditional methods like injection molding or machining, it is less expensive to make prototypes with this technique.

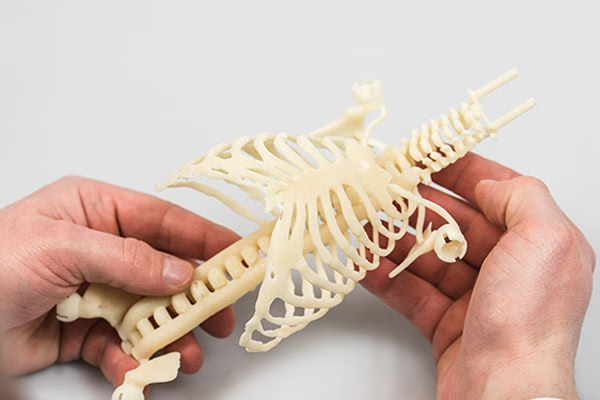

Medical 3d printing products

Less Wastage

3D printing can produce complex designs that are too difficult to make using traditional techniques. Designers preferred this method because they can make prototypes and test them in less time and money. There is also less material waste and you don’t have molds to scrap. 3D printing will only print using the exact quantity of materials without any wastage.

Because the design to prototyping step is fully digital, there is no additional step using traditional prototyping. What you have is expedited prototyping, where designers can immediately identify the flaw that will take months if you will use traditional manufacturing.

As a result, with 3D printing, you can make quick decisions on the final part designs with less waste and reduced cost.

Improved Product Quality

One major advantage of 3D printing is it allows high-quality design and process development. Since additive manufacturing allows product designers to determine the flaws early on and improve, you can expect nothing but quality parts with improved design.

Also, the technological advancements in 3D printing have allowed product engineers to create complex and intricate details that other manufacturing methods cannot do. There are no limitations to the traditional machine and the tools that are needed to complete the part.

When it comes to materials, 3D printing can use different types like thermoplastics. Some of these materials are lightweight but have retained their integrity and strength.

Conclusion

3D printing not only revolutionized the way products are made. It has also brought with it plenty of benefits including time and money savings. If you are interested to know more about 3D printing and what it can do for your project. Contact Nice Rapid. They offer advice for the best 3D printing technologies to use.