Did you know that we cannot go through our day without encountering a polyurethane product? These products are durable due to the combination of various urethane polymers. These materials add strength and flexibility to a wide range of applications.

Polyurethane, a synthetic-based resin, is found in a limitless number of household products like paint, varnishes, and adhesives. In some cases, they are also used as a replacement for sturdy materials like wood.

The introduction and succeeding flooding of polyurethane materials in the manufacturing industry has opened doors for new applications. As the popularity of polyurethane increases, so does the polyurethane casting process. It leads to the creation of new manufacturing techniques that are less costly but more efficient. We are talking about vacuum casting.

Advantages of Polyurethane Casting or Vacuum Casting

Vacuum casting provides a handful of benefits including its flexibility in design and production and the lesser production costs. It is beneficial when creating prototypes or when improving an already existing product without completely changing the process. The most common benefits of choosing vacuum casting can be summed up in the following:

- Fast turnaround of molds

- Increasing flexibility when designing the master patterns

- More color options

- Lower cost of initial production

- High fidelity to the molding options particularly on surface detailing

- These advantages are not complete as more things can be accomplished when using the process.

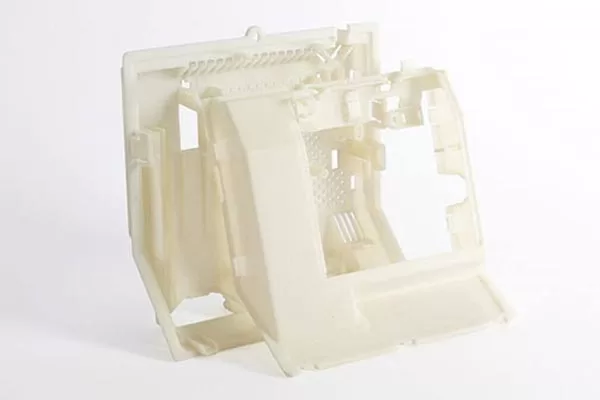

ABC type PU vacuum casting

Introduction of Vacuum Casting in Polyurethane-based Production

The most common casting process using polyurethane materials is vacuum casting. The manufacturing technique is also known as resin casting. It is a highly adaptable form of production used to create various parts for practical applications.

The materials used in the casting process are sometimes not 100% polyurethane as small amounts of plastic and cast nylon are also used. This process is an option where injection molding is not cost-effective, but there is a demand to show the precise details on the surface of the product.

One of the reasons why vacuum casting is an effective polyurethane casting process is because of its range of materials available and can be used. There is a wide range of options to build a part or products allowing limitless combinations of texture and hardness, along with revolutionary features like transparent component combination or color matching. These are complete game-changers in the manufacturing industry as no other technique can deliver this. With these options, product designers and engineers have plenty of room to play to show their creativity and ingenuity.

Another benefit of using vacuum casting is its versatility that brings along cost-saving and efficiency. These are critical when time is of the essence for building prototypes or master models.

Over molding is also possible with vacuum casting. Here manufacturers can combine different types and hardness of plastic in a single part. It can be applied to any engineering workflow and delivers consistency with the finished product.

Conclusion

The polyurethane market continues to evolve at an accelerated pace. By staying on top of emerging processes and production trends, companies can juggle multiple projects on their pipeline. That is why it is important to partner with a company that can guide them through the nuances involving the polyurethane casting process.