In the past, the manufacture of goods and products used to take a lot of time; a lot of effort and manpower had to be put in for a product to successfully get to the market. But nowadays all that has changed.

Clients are demanding high-quality products and manufacturers have to keep up with the ever-changing needs. There is stiff competition amongst manufacturers to meet every need and preference of their clients, if your product doesn’t meet a certain standard, sorry to say but you’ll become obsolete.

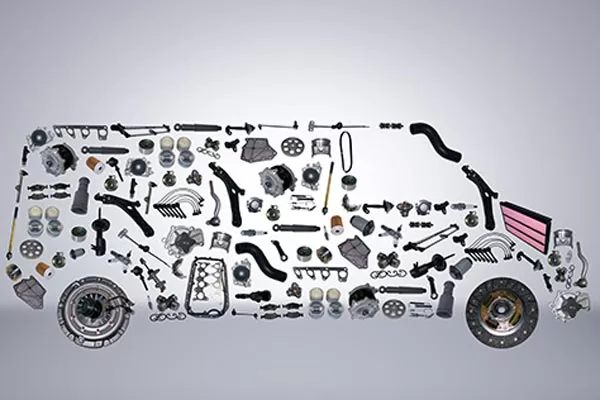

Automotive parts

If you want to stay relevant for a long time to come, low-volume manufacturing is the perfect option for you as it will enable you to stay ahead of the pack.

High-quality production is now a possibility

With low-volume manufacturing, it’s now easy to ensure your output is of high quality. At the moment the market is filled with competition, the only people who can survive are those who are innovative and constantly introduce new products increasing their chances of success.

This increased competition puts pressure on every firm or manufacturer to stay ahead of their competitors which is a win for their customers. Now developers and engineers can create a high-quality product within the shortest time possible.

Low volume manufacturing will provide you with better support chains as well as manufacturing supply allowing for products to be produced at a faster rate compared to large-scale production. Firms now have the opportunity to work based on customer trends.

When a product proves to be a hit with clients, you can use low-volume manufacturing to avoid huge costs and investments. It’s a well-known fact that products don’t last for long, people are only interested in high-performing products for a short time.

As a result of these changes, most manufacturers prefer low-volume manufacturing compared to large-scale production.

Providing you with a bridging option

Low-volume manufacturing provides you with an opportunity to bridge production options between mass-production and prototyping. For firms that want to stay ahead of the competition will take full advantage of this manufacturing technique.

For many firms, they opt for low-volume production as its economical and cost-effective. A lot of start-ups can’t begin with expensive and high-end production, with this technique; the risks associated with production are significantly scaled-down providing you with a certain degree of flexibility. With low-volume manufacturing, producers get better opportunities and options.

For the success of your project, your team needs to be simple with routing and processing, sequential processing is the way to go and can be implemented for future success. For those who want flexibility, it’s important to incorporate low-volume manufacturing into your production process.

If the initial investment is a bit limited, then low-volume production will enable you to attain your end objective. This technique promotes creativity allowing you to create a more appealing product with excellent aesthetics that will prove to be a hit with consumers.