Forget mass production and cookie-cutter products. Low-volume manufacturing is where it’s at! This approach is all about flexibility, customization, and the ability to produce goods quickly and efficiently in smaller quantities. It’s the perfect solution for businesses that want to cater to niche markets, offer personalized products, or test new ideas without breaking the bank. Let’s explore how low-volume manufacturing is changing the game.

Mass Personalization: Giving Customers What They Really Want

In today’s world, customers crave unique products that reflect their styles and needs. Mass personalization is the answer, and low-volume manufacturing is the key to making it happen.

Think custom phone cases with your initials, sneakers designed to your exact foot measurements, or even personalized skincare products tailored to your skin type. Low-volume manufacturing allows businesses to offer this level of customization without the massive overhead of traditional mass production.

This means you can cater to niche markets, offer limited-edition products, and create a sense of exclusivity that resonates with customers. It’s about giving people what they want when they want it and exactly how they want it.

3D Printing and Rapid Prototyping: From Idea to Reality in Record Time

Remember the days when prototyping a new product took months of back-and-forth with manufacturers and expensive tooling costs? Those days are long gone, thanks to 3D printing and rapid prototyping.

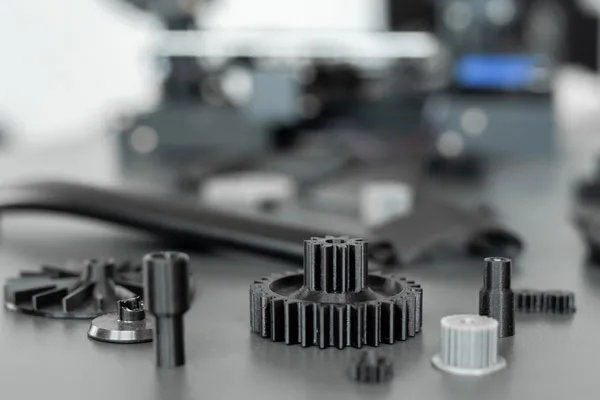

These technologies are a perfect match for low-volume manufacturing, allowing you to quickly create prototypes, test designs, and iterate on ideas without the time and expense of traditional manufacturing methods.

Need to test a new design for a custom bike part? 3D print it. Want to see how a new ergonomic handle feels in your hand? 3D print it. This rapid iteration allows you to refine your product and get it to market faster, giving you a competitive edge.

3D printing parts

Applications of 3D Printing and Rapid Prototyping Across Industries

Automotive Industry

Automotive manufacturers use 3D printing to create prototypes of complex components like specialized engine parts, reducing the time taken to test and implement new designs. This accelerates the innovation cycle, allowing companies to adapt faster to changing consumer preferences and regulatory requirements.

Healthcare

In the medical field, rapid prototyping is revolutionizing the development of customized prosthetics and implants. Surgeons can create patient-specific models based on individual anatomical data, ensuring better fit and functionality.

Consumer Goods

Companies producing consumer products, such as kitchen gadgets or electronic accessories, leverage 3D printing to refine their designs based on user feedback. This iterative process ensures that the final product aligns closely with market expectations and user needs.

Aerospace

The aerospace sector benefits significantly from the lightweight structures made possible by 3D printing. Prototyping components that adhere to strict weight and safety regulations can be conducted more efficiently, enabling airlines and manufacturers to innovate rapidly while maintaining compliance.

E-commerce and Online Platforms: Connecting with Customers Worldwide

Low-volume manufacturing and e-commerce go hand-in-hand. Online platforms provide a global marketplace for businesses to showcase their unique products and connect with customers around the world.

Forget about the limitations of brick-and-mortar stores and traditional distribution channels. With e-commerce, you can reach a wider audience, test new markets, and build a loyal customer base without the overhead of physical storefronts.

This is particularly beneficial for low-volume manufacturers, who can often fulfill orders on demand and ship directly to customers, reducing inventory costs and minimizing waste.

Many online platforms also offer tools and resources to help businesses manage their production, track orders, and connect with suppliers, further streamlining the low-volume manufacturing process.

The Benefits of Low-Volume Manufacturing: Flexibility, Agility, and Efficiency

Low-volume manufacturing offers a number of advantages over traditional mass production:

- Flexibility: Quickly adapt to changing market demands and customer preferences.

- Agility: Respond to new trends and test new product ideas with minimal risk.

- Efficiency: Produce goods on demand, reducing inventory costs and waste.

- Customization: Offer personalized products and cater to niche markets.

- Reduced Lead Times: Get products to market faster and meet customer expectations for quick delivery.

Low-volume manufacturing is empowering businesses to create unique, high-quality products that meet the demands of today’s discerning customers. By embracing technologies like 3D printing, e-commerce, and on-demand production, businesses can thrive in a world where customization and agility are key to success.