NICE Rapid Blog

Latest news and knowledge to share.

Plastic Injection Molding: From Concept to Reality (And Why It Matters)

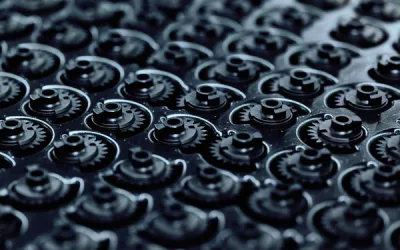

Plastic injection molding is everywhere. Seriously, just look around. From the sleek headphones you wear to the keyboard you're typing on, and the housing of your smartphone, plastic injection molding is likely behind their creation. But what exactly does this...

Low-Volume Manufacturing: The Power of Customization and On-Demand Production

Forget mass production and cookie-cutter products. Low-volume manufacturing is where it's at! This approach is all about flexibility, customization, and the ability to produce goods quickly and efficiently in smaller quantities. It's the perfect solution for...

Sheet Metal Fabrication Bending and Shaping the Future

Sheet metal fabrication is a cornerstone of modern manufacturing, enabling the creation of everything from sleek electronic enclosures to robust industrial machinery. This versatile process transforms flat sheets of metal into precise, functional components using a...

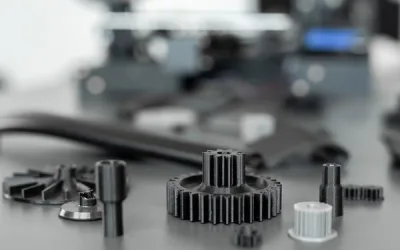

Mono-Operative Molding

Mono-Operative Molding is a new concept in the injection molding field, in which one engineer is in charge of the entire production process, from writing the DFM to actually producing the product that is sent to customers. The basic premise is to cut production times...

Innovating with Blow Molding for Custom Plastic Solutions

When you think about everyday plastic products, it's easy to overlook the technology behind their creation. But behind the scenes, blow molding is hard at work, shaping some of the most common, yet highly functional, items we use daily. From plastic bottles to...

Storage & Care of Your Mold

At NICE Rapid, we are well aware of how much of an investment you are making when you trust us to manufacture a mold for you. Not only are you trusting us with your intellectual property, but you are also expecting us to care for and store your mold to the highest...

5 Ways Rapid Prototyping Can Save You Money

Developing a new product is an exhilarating adventure fueled by creativity and innovation. But as any seasoned explorer knows, even the most exciting expeditions require careful planning and resource management. In the world of product development, that translates to...

Plastic Injection Molding Gets a Tech Upgrade: Smarter, Faster, and Greener Than Ever

Remember those plastic building blocks you played with as a kid? Or that cool action figure? Chances are, they were made with plastic injection molding. It's a process that's been around for ages, but trust me, it's not your grandpa's manufacturing anymore! Thanks to...

Rapid Prototyping Design Thinking

We have already looked at the stages that are used in order to create a product. It is very clear to see that prototypes are some of the most crucial parts of these stages, as they allow us to test our design in the real world and to check whether our choices of...

Producing Your Prototype in China

Firstly, You have to be able to create your design at least on paper, Or even better, using a specialist piece of Computer Aided Design or CAD software, In order for the rapid prototyping specialist, Such as NICE Rapid, To be able to create the mold and produce your...

Pressure Die Casting Beyond the Basics

Pressure die casting, a metal casting process that involves injecting molten metal into a steel die under high pressure, is a versatile technique that consistently delivers precise, high-quality parts with excellent surface finishes. This reliability is a testament to...

5 Must-Have CNC Machining Features for Faster and More Precise Prototypes

In today's fast-paced product development world, rapid prototyping is no longer a luxury—it's a necessity. It allows you to transform ideas into tangible objects, identify potential issues early on, and refine your design through real-world testing. While various...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.