NICE Rapid Blog

Latest news and knowledge to share.

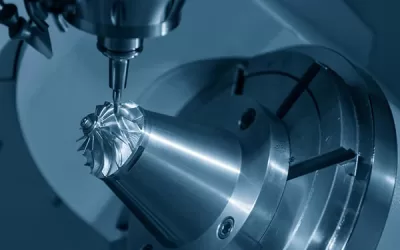

CNC Machining and AI: Can It Work?

We have seen an increase in the use of artificial intelligence in the past few years. In manufacturing, CNC machining is one of the processes that took advantage of the benefits of AI. CNC machining is one of the most common techniques used in every industry. From the...

An In-Depth Look at the Rapid Tooling Process

Rapid tooling and rapid prototyping are frequently used interchangeably in the manufacturing realm. What is the difference between the two and when is rapid tooling used? Rapid Tooling refers to the process when rapid prototyping techniques and conventional tooling...

How to Achieve Efficiency with Low Volume Manufacturing

Low volume manufacturing refers to the production of 10,000 to 100,000 parts, depending on the manufacturing technique used, the processes involved, the tooling, and materials, among others. It is a strategy used by many companies when introducing a new product...

5 Common Applications of Silicone Molding

Molds have been a constant figure in manufacturing. From the artisans who made weaponry during the Bronze Age to the modern-day consumer products manufacturers, they use molds to shape them. While the early molds are made from stone, modern science gave birth to...

Rapid Prototyping as an Agile Strategy in Product Development

Companies need to develop and introduce new products faster to be competitive in this fast-moving consumer-centric market. Since organizations need to be fast on product development and innovations, rapid prototyping is a crucial element in this department. Rapid...

How to Choose the Best Finishing Services for Metal Products

Metal is the most common material for high-quality commercial and industrial products. While it does a great job of adding function, durability, and strength, having the right type of finishing service can add even more value to the product. Several metal finishing...

Plastic for CNC Machining: A Guide on How to Select the Right Material

When you have a part designed, the first thing to determine is what material it should be made from. If you have decided that it will be plastic and will use CNC machining as your manufacturing technique, the process will not stop here. There is a wide range of...

Silicone Rubber A Short Discussion of Its Types, Benefits, and Drawbacks

Silicone is composed of high-performance materials with a unique molecular structure. It comes in different forms, including solids, liquids, semi-viscous pastes, greases, oil, and rubber. The most common type that we are familiar with is silicone rubber. Most...

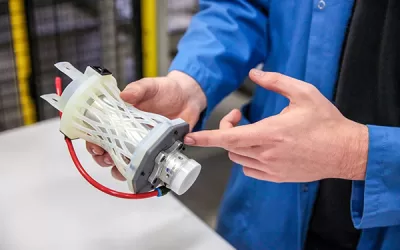

Why is Vacuum Casting a Preferred Method in Prototyping

There are many options to choose from when it comes to prototyping. There is CNC machining, 3D printing and then there is vacuum casting, which can be used as an independent technique or as a perfect complement to the two aforementioned processes. Many articles have...

How Rapid Tooling Has Revolutionized Prototyping

Do you want to get your products to market faster than your competition? If yes, you need access to different rapid prototyping processes to manufacture the parts for testing and evaluation. The demand for faster and less expensive tooling solutions brought about...

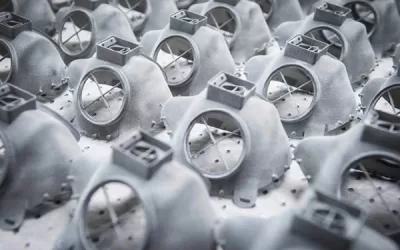

How 3D Printing Supports Supply Chain During the Pandemic

Before the pandemic, the global supply chain was so productive and reliable that it was not visible to its customers. It was running efficiently in the background so, we don’t expect to encounter issues with it. However, many industries are experiencing issues with...

7 Finishing Services for Metal Surfaces and their Benefits

Here is one thing you should know: all metal prototypes and CNC machined parts will have characteristic scratches on their surface. The depth and look of the scratches depend on the cutting tool and the material the components are made. In some cases, you can ignore...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.