NICE Rapid Blog

Latest news and knowledge to share.

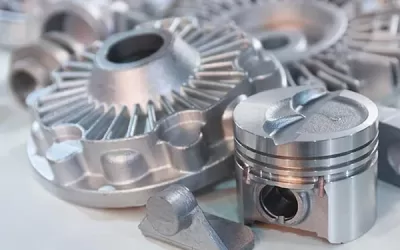

The Advantages and Disadvantages of Pressure Die Casting

One of the most popular metal casting methods is die casting. It is known for its versatility and the number of products it can produce. There's a wide range of factors that allow this process to produce intricate product designs to fulfill advanced engineering...

What is Production Tooling in Manufacturing?

Tooling is the heart of the production process. Tooling determines product quality, ensuring it meets manufacturing specifications. Rapid prototyping requires different types of tooling in each project phase for successful outcomes. This post unpacks the critical role...

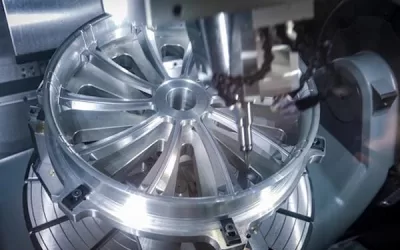

The Advantages of Using CNC Machining for Car Parts

The automotive industry relies heavily on CNC machining for prototyping and mass manufacturing of OEM and generic parts. It's useful in the prototyping phase, allowing manufacturers to identify design flaws and make changes. CNC machining allows for one-off runs in...

The Finishing Services for Rapid Prototyping

The rapid prototyping process involves the production of components for use in prototype models before entering the mass production phase. Manufacturing partners can produce prototype components in a variety of surface finishes, depending on customer requirements....

Vacuum Casting Materials, Applications, Guidelines, & Advantages

Otherwise known in the industry as polyurethane or urethane casting, the vacuum casting process for prototyping utilizes silicone molds to manufacture rubber and plastic components under a vacuum. This rapid prototyping and manufacturing process is highly adaptable to...

Everything You Need to Know About CNC Milling

The invention of CNC milling stretches back five decades. Since its inception, Computer Numerical Control machining garnered a reputation for automation and precision in product prototyping and manufacturing, leading to the development of three and five-axis machining...

Benefits of CNC Machining for Medical Products and Parts

The medical industry demands accuracy, precision, and reliability in product prototyping and development to ensure product quality and efficacy. CNC machining is a popular choice for rapid prototyping and production in the medical device sector. The technology's...

Advantages of Anodizing for Surface Finishing

The first use of anodizing technology was for protecting seaplanes from seawater corrosion. British inventors Stuart and Bengough filed a patent application for their anodizing process in 1923. The pair implemented anodizing services on an industrial scale the same...

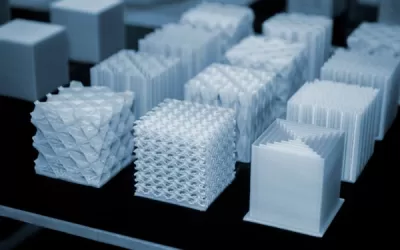

What are the Advantages of Rapid Prototyping?

Every year, more than 30,000 new products launch into the market. With so many additions, how can your product stand out from the competition? Prototyping offers manufacturers a useful tool in the product development stage, giving them a replica of the finished design...

5 Overmolding Applications in our Life

Have you ever wondered how brands make the grip parts on toothbrushes or plastic cooking spatulas? Molded objects can receive a second resin layer in the TPU injection molding process, aka "overmolding." The result is a product with a combination of materials and user...

Silicone Molding Products for Makeup Products

Makeup is a billion-dollar industry, with companies investing millions in product research and development. Silicone molding offers an attractive manufacturing process for mass-producing products at scale for global distribution. Manufacturers can assist brands with...

5 Ways of Texturing Injection Molds for Different Product Finishes

Today, manufacturers and prototype designers have their choice of finishes in plastic injection molded parts. The possibilities for finishes of final products allow better levels of innovation and creativity to come bubbling to the surface in the design process. The...

Prototype and Manufacturing Services Near By

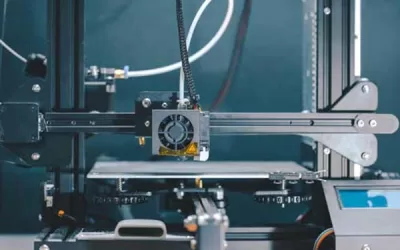

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.