NICE Rapid Blog

Latest news and knowledge to share.

What Makes One of The Best Production Techniques?

The production sectors have witnessed a significant shift in recent years, companies now can create complex and intricate geometries partly thanks to liquid silicone rubber molding. Liquid silicones rubber molding has been around since the 1970s and has become the...

The Difference Between Rapid Tooling and Conventional Tooling

A critical step in manufacturing is tooling. This step involves producing the tools that will help create the product, and it includes cutting equipment, molds, jigs, dies, other custom parts. Manufacturers have lots of options in completing this process, and they...

Why Liquid Silicone Rubber Molding is Ideal for Medical Products

Material performance is significant in any application, even more so when the lives and health are at stake. One of the particular challenges in finding a material that is viable for medical application is tough enough to withstand heat, chemical exposure, and...

Vital factors you need to consider when using low volume manufacturing

The use and application of low-volume manufacturing have been on the rise in recent years? But what is low-volume manufacturing by definition? They are no clear and concise definition of low-volume production as its subjective and its definition depends on the type of...

Low Volume Manufacturing and the Future of Industry

In the early days of manufacturing, products were made one by one. However, times changed when the demand for faster and cheaper products entered the picture. It has led to the factories we have today and, of course, mass production. Nowadays, these factories can...

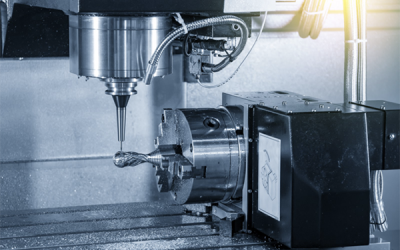

CNC Machining – Understanding the Three Major Ideas to Machining Parts

When talking about running parts in CNC machining, it's crucial to understand the function of three major components. Understanding and knowing these components will make the issue of running parts easier. These components are routine, rhythm, and system. If you want...

Some of The Most Common Issues Associated with Plastic Injection Molds Projects

Let's just take a brief moment and appreciate how one plastic injection mold has transformed the whole manufacturing process making everything seamless and easier compared to traditional methods. Well even though plastic injection molding comes with a lot of benefits,...

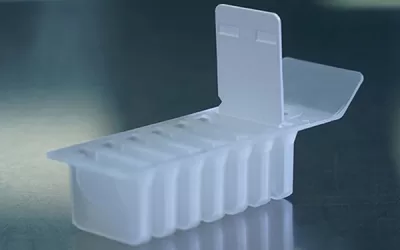

Plastic Injection Molding – Why Many Companies and Businesses Use This Production Process

There are a few reasons why numerous companies select to utilize plastic injection molding. The foremost prevalent reasons incorporate; the in general costs are lower, higher proficiency, and the capacity to utilize numerous plastic sorts. Plastic injection molding is...

Various Methods of Rapid Tooling Used Worldwide

Rapid tooling is categorized into two – Indirect and Direct approaches. The indirect category involves the use of RP master patterns in creating a mold. The direct, on the other hand, use the RP machine in building the core and cavity mold inserts. The increasing need...

Vital Aspects You Need to Know About Low-Volume Manufacturing

There is no doubt that the modern product design stage has undergone a tremendous shift, but one sticking point that has been quite a challenge for most producers is the lifespan of the products after they hit the market. Due to longevity, the products might end up...

Tips for Effective Use of Compression Molding

Compression molding is one of the simplest and easiest fabrication techniques used in various manufacturing sectors. The entire process is quite simple and straightforward as it pertains to the insertion of the material onto the mold, closing, and finally, heat and...

Basic Facts on CNC Milling Machines

There are several things revolutionized nowadays in the industry. Everyone is looking for the best way to reduce the labor efforts to make the way perfect to save a good amount of money during production. Those who are seeking the best way of making the process of...

Prototype and Manufacturing Services Near By

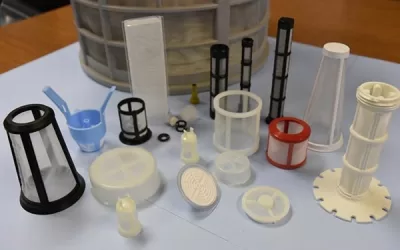

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

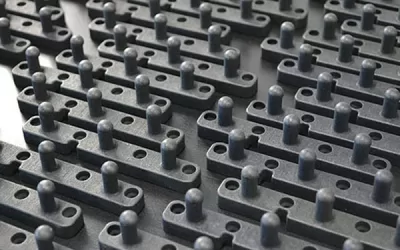

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.