NICE Rapid Blog

Latest news and knowledge to share.

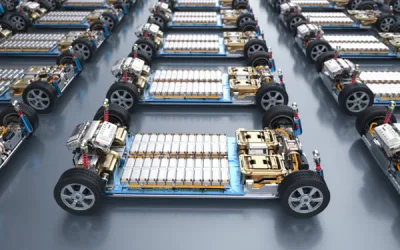

EV Battery Pressure Die Casting Solutions for Enhanced Efficiency and Durability

When it comes to EV battery manufacturing, selecting the appropriate die casting process is crucial for both performance and durability. Pressure die casting offers a precise and efficient method for producing battery housings and components that meet stringent...

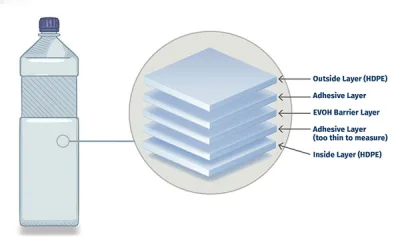

Multi-Layer Blow Molding for Pharma Enhances Packaging Integrity and Safety

Multi-layer blow molding is a specialized process used in the pharmaceutical industry to create containers that offer superior barrier properties and product protection. You benefit from enhanced control over material layers, which improves shelf life and maintains...

Die Casting for 5G Enclosures Enhances Durability and Signal Integrity

When designing enclosures for 5G equipment, the choice of material and manufacturing method is crucial in meeting performance and durability standards. Pressure die casting provides a precise and cost-effective method for producing robust, lightweight metal enclosures...

Sheet Metal vs 3D Printing Choosing the Right Manufacturing Method

Manufacturing choices affect your product’s success, cost structure, and market competitiveness. We see this in sheet metal fabrication and 3D printing, which are very different methods of producing parts and assemblies. What you choose between them will, in turn,...

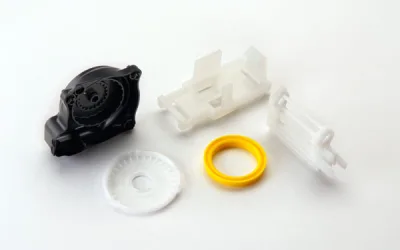

Emerging Trends in Plastic Injection Molding: Innovations Shaping the Future in 2025

Plastic injection molding is experiencing a rapid and continuous evolution, driven by groundbreaking technological innovations, increased environmental awareness, and increasing demand for highly accurate and functional components. In 2025 , the industry is...

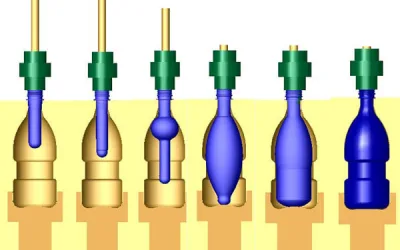

Blow Molding for Containers: An Essential Process in Modern Packaging Solutions

Blow molding is a revolutionary process for producing containers, allowing various shapes and sizes to be created efficiently. This manufacturing technique enhances production speed and results in lightweight and durable containers that meet diverse industry needs. As...

Pressure Die Casting for Aerospace Parts: Precision Manufacturing for High-Performance Components

Pressure die casting is an essential manufacturing process tailored to produce intricate aerospace components with precision and efficiency. This method excels in creating lightweight, high-strength parts that meet the industry's rigorous standards. In demand for...

Blow Molding: A Comprehensive Guide to Hollow Container Manufacturing

From the water bottle in your hand to the gas tank in your car, blow molding creates countless hollow plastic products we use daily. This versatile manufacturing technique is the go-to method for producing lightweight, durable containers at scale. Ready to dive into...

Exploring the Advantages of Pressure Die Casting in Modern Manufacturing

Ever marveled at the sleek metal components in your car or smartphone? Chances are, pressure die casting helped bring them to life! When manufacturers need complex metal parts with jaw-dropping accuracy and mirror-like surface finishes, pressure die casting is the...

Liquid Silicone Rubber Molding: Precision Manufacturing for Complex Components

In today's global supply chain landscape, liquid silicone rubber molding has emerged as a premier technology for producing high-quality elastomeric parts with complex geometries. As companies navigate rising production costs and material shortages, this specialized...

Pressure Die Casting for Consumer Durables: Enhancing Quality and Efficiency in Manufacturing

Pressure die casting is a manufacturing process that allows for the mass production of high-quality metal components. This technique is particularly advantageous for consumer durables, enabling precision and consistency in creating complex shapes. This method can...

Plastic Injection Molding for Smart Factories: Enhancing Efficiency and Production Flexibility

As smart factories revolutionize manufacturing, plastic injection molding emerges as a crucial technology, enhancing efficiency and precision in production processes. Integrating automation and real-time data analytics allows you to produce complex plastic components...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.