When you have a part designed, the first thing to determine is what material it should be made from. If you have decided that it will be plastic and will use CNC machining as your manufacturing technique, the process will not stop here.

There is a wide range of plastic materials that you can use for your project. Here is a short guide to help you choose the right one.

Plastics for CNC Machining

Plastic is an integral part of the modern manufacturing industry. This material is readily available, affordable, and is compatible with many manufacturing techniques including 3D printing, injection molding, and CNC machining.

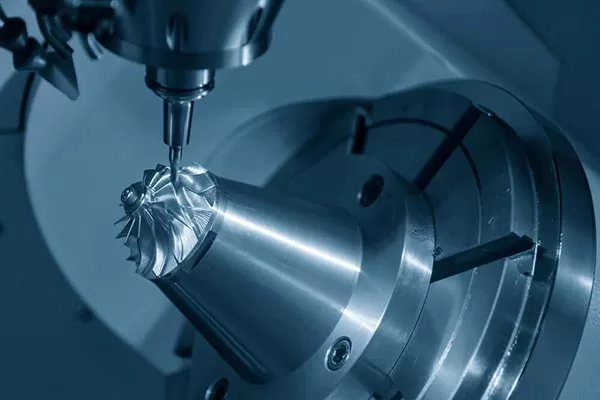

CNC machining belongs to the subtractive manufacturing process that involves employing rotating tools and drills to remove the materials from a solid block of the workpiece. In producing plastic parts, CNC machining is more precise than injection molding

Aside from precision, CNC machining is also compatible with different kinds of plastic than other manufacturing methods.

Factors to Consider when Choosing the Plastic Type for CNC Machining

Choosing the right material can make a difference between optimal outcomes and mediocre results. Some plastic might not be a good fit for the design you have. To know the perfect plastic material for your CNC machining project, here are some factors to consider.

- Internal and External Environment: you need to consider the environment where you will use the machined parts. If you need it to withstand moisture, rusting, or any external temperature while keeping the structural integrity maintained, then find one.

- Stress Loads: the tolerance of the machinable plastic part is also important. It should be able to bear high-stress load,

- Fastening: Some designs require fastenings. For them to be durable, you need a plastic that has strength, corrosion resistance, and even galvanic resistance.

- Operating Temperature: You should also consider the temperature where the CNC machined part will be used.

- High Temperature: The plastic should be able to withstand high temperatures. If heat tolerance is not an issue, you can choose any material, which you think is suitable.

CNC machines

Plastic Materials Ideal for CNC Machining

There are a plethora of materials that can be used from CNC machined plastic parts. Take a look at the types of plastic that you can consider.

- ABS – They are the most common plastic for CNC machining. They are affordable, offer electrical resistance and high impact resistance because of their toughness. The only downside with ABS is it’s not chemical or abrasion-resistant.

- Nylon – Another commonly used plastic for CNC machining, they are preferred by machining experts because of their durability and high tensile strength. Aside from this, it is also chemical and wear-resistant. However, nylon tends to swell when exposed to excessive moisture.

- Acrylic – This plastic has the most resistance to scratches and impact. But they are also brittle and are prone to cracking and shattering.

- Delrin – This type of plastic is ideal when lots of friction is needed. They are stiff and have excellent stability. The only problem with Delrin is they can be difficult to link.

- HDPE – High-density polyethylene plastics are commonly used in everyday products. It has a slippery surface and works well with chemicals. It also has excellent electrical insulation. However, this material is difficult to machine.

- Polycarbonate – The last on our list is one of the sturdiest and most robust types among machinable plastics. They are not scratch proof but have extraordinary impact resistance and stiffness.

Conclusion

CNC machining is a versatile manufacturing process that allows product designers and engineers to produce high-quality parts. Since it is compatible with any manufacturing process, there are plenty of choices available, including plastic. A manufacturing expert like Nice Rapid can help you shorten the material selection process. Contact them for your project.