by Nice Rapid | Jul 17, 2024

Post Processing for Direct Metal Laser Melting (DMLM) 1. Loose Powder Removal In DMLM, the powder that is not fused during the build will remain in loose powder form. The process of removing the loose powder is pretty straightforward, often performed with brushes or...

by Nice Rapid | Jun 27, 2024

Design Guidelines for Vacuum Casting Design Opportunities Vacuum Casting is a very versatile process that has many advantages for designers. Vacuum Casting tooling is flexible silicone that allows undercuts can be ejected by flexing the tool rather than increasing the...

by Nice Rapid | Apr 9, 2024

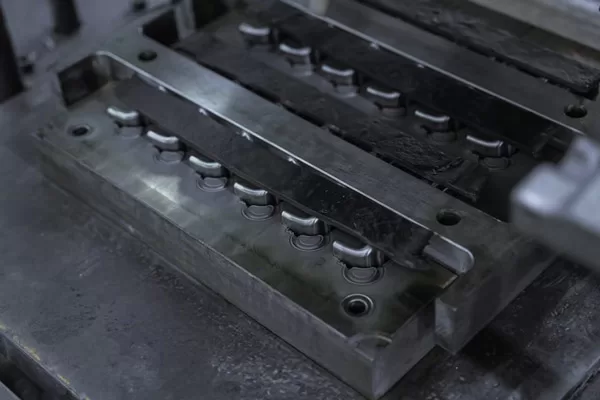

How to Prevent Injection Molding Flash? Flash is a common defect in injection molding, describing the thin layer protruding from the mold parting line or areas around the mold where two contradictory surfaces meet, forming a physical boundary. Such areas create...

by Nice Rapid | Mar 10, 2024

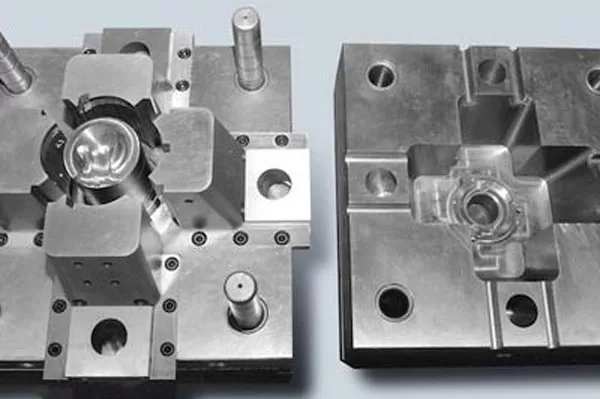

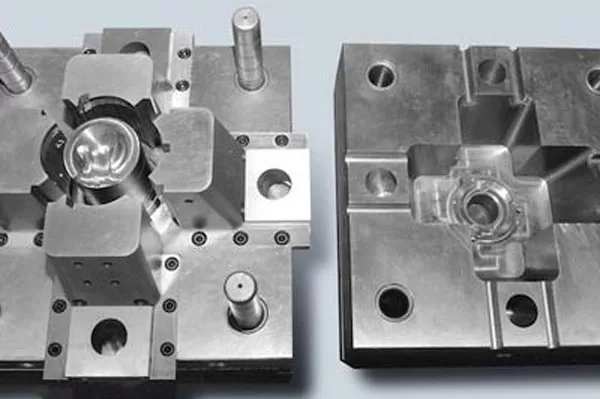

The Importance of DFM Report for Rapid Tooling The Benefits of DFM Design for Manufacturing (Design for Manufacturability), also known as DFMA (Assembly), is a manufacturing process commonly used to produce rapid tooling for the prototyping process. It’s a key...

by Nice Rapid | Nov 30, 2023

How to Make a Silicone Mold for Rapid Prototyping Rapid prototyping projects prove concepts and prepare the stage for the product to enter the mass manufacturing phase. Silicone molds are a preferred production choice for low and high-volume applications, making...