Your hunt for a plastic injection molding workshop begins when you design a new product that requires the procedure. You also need these services if your company is keeping up with the times and redesigning the core line of products to be competitive in the market.

Manufacturing methods evolve, and most companies find out the hard way because they get comfortable with the old ways of doing things until it hits profits. There are still many questions regarding improving the manufacturing industry, but you can get some answers by choosing a suitable workshop.

The following are some of the most common questions you need to ask before starting a partnership with a service provider.

Should you work with a manufacturer who has In-house mold tooling?

Working with a plastic injection molding manufacturer with an in-house team to manage your orders since they’re conceived is the best course for any developer. This decision, however, relies heavily on the budget you have in place. Regarding logistics, all details can be sorted out in real time with the team of designers and technicians to shorten the delivery time of your part. The workshop you chose has the option to deliver a prototype. You can save a lot of money since you won’t have to shop around your CAD plans to other companies.

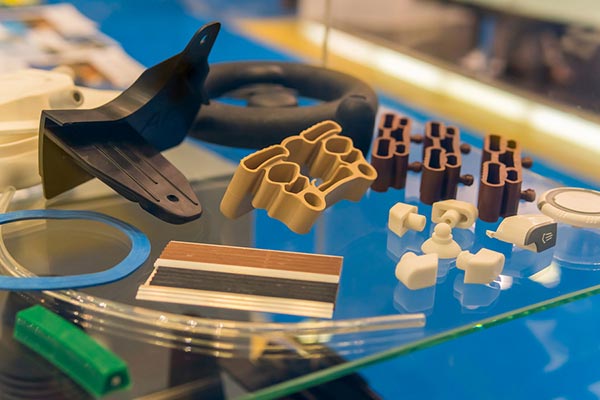

Plastic parts

Should the use of molding technology be a deal breaker for your project?

This is a subjective point since most plastic injection molding manufacturers work to the best of their capacities with the hardware they have. Most workshops allocate all their resources to offer the best-finished products, especially if they are working with a large corporation. Even in these scenarios, these companies use their resources, including mold-making technology, to the best of their capacities. This becomes a deal breaker if the prototypes fail to perform to the specifications required, meaning that making more than one would not be out of place. Even if your company is small, you need not worry. The high demand for these services ensures these companies do their best to avoid losing clients to competitors.

Should you be concerned about the longstanding mold guarantee for a project?

This question also hinges on some of the factors that can affect the mold’s performance for your product, depending on the type of project being developed. If you need a durable mold for an extensive run of products, but your budget won’t allow for it, you may have to rethink your strategy and go with lower volumes for the first orders. Keep in mind it’s not the workshop’s job to make calls on business decisions on your end, but they can recommend the best course of action. In cases like this, a cheaper mold would be the best way to go along a short run of parts. Once you consolidate your product in the market, you can increase new orders to heftier molds and large runs of products to be shipped.