Companies need to develop and introduce new products faster to be competitive in this fast-moving consumer-centric market. Since organizations need to be fast on product development and innovations, rapid prototyping is a crucial element in this department.

Rapid prototyping can achieve the following objectives:

- Facilitate faster product development – Rapid prototyping plays an important role in creating a successful product.

- Validation of early-stage design/concept, including testing for form, fit, and function of the design

- Verification of the final stage of the product before going to full production

- Provide end-users, clients, and customers, among other first-hand experiences of the product and provide feedback.

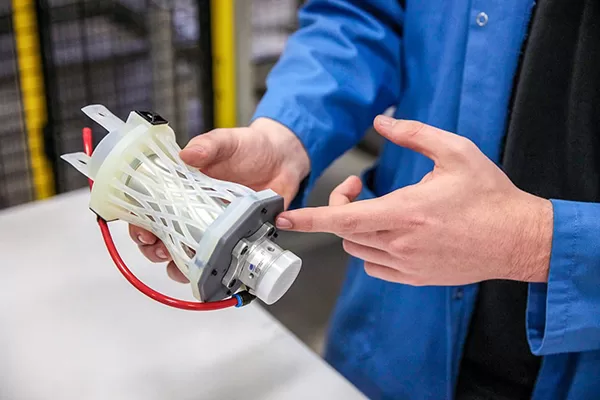

Rapid prototyping products

What is Rapid Prototyping?

Rapid prototyping is an agile strategy and value to the product development process. With this approach, a three-dimensional model of the product can be created and tested to optimize its characteristics like size, shape, and usability.

Creating product simulations is important in creating a product as multiple iterations can come up in a short period based on the user’s feedback and analysis.

Prototyping is a means to validate the hypothesis that the product can solve the problem that it is intended to solve. Although it may not be exact functionally, it often resembles the final product allowing potential users to interact with the product and provide their feedback.

If the feedback is positive and there are minimal changes required on the product, then it will save the company weeks or months from manufacturing something that will not work in the end. Another benefit of prototyping is if the feedback is positive, it means that the concept is on the right track and the development should go forward.

The “rapid” part of rapid prototyping describes the speed by which the initial prototype is made and how quickly the stakeholders can gather the feedback and analyze it. It will also indicate how fast the iterations can be done using the same process.

Product designers and engineers should find a delicate balance between creating a product model that looks close enough to the final product to get genuine reactions from prospective users but should not spend a lot of time and effort on it. It will limit their will to implement revisions because they have invested a lot in the prototype.

Importance of Rapid Prototyping to Product Managers

Product managers need to appreciate the importance of rapid prototyping. Getting actual customers to test a prototype will give them ideas on what works and what doesn’t in creating a product that matches the user’s needs and shortening its time to market. When they can validate the assumptions and uncover the faults earlier in the process, the product team can proceed with confidence that the final product will be successful.

Since rapid prototyping can be repeated in a short period, it facilitates one testing after another. They can provide input to the developers and manufacturers creating the prototypes, quickly analyze usage and feedback and recommend changes for the next round.

Conclusion

Rapid prototyping is invaluable to the manufacturing industry. It saves the team from wasting their time and from disaster. It provides dependable feedback from users who interacted with the prototype for product managers to have a qualitative validation of their assumptions or indications of adjustments required. It also helps reduce the risk of the final product failing to meet the objectives.