Within the metal, work shaping forms a sheet is essentially any metal structure that contains an expansive surface and essentially a lean width. The length of the distortion is caused by the sum of bendable quality, shearing speed moreover exceedingly impacts the arrangement of the working metal sheet. When building structures like cups the sheet shaping handle employments the clear and punch handle where the required portion of the sheet is fundamentally cleared out. The clearance is exceptionally imperative since it appears the conclusion result of the shearing fabric. Drive is more often than not connected at the best of the plastic arrangement on the sheet metal so that it can break.

Sheet Metal in Comprehensive Details:

Unnecessary to say, a larger part of the sheets are more often than not underneath 6mm in width. Sheets have a wide run of exercises they can do. A few of the items created from the sheet metal forms include plane parts and car parts. A few sorts of, metal sheets e,g aluminum fundamentally have a memory. This essentially implies that you just ought to correct a parcel of pressure so that the aluminum can make an unused shape without going back to the initial shape. Additionally, each sheet metal handle is decided moreover by the sort of metal. A few metal sorts like Press are more often than not simpler to structure and design.

The Shearing Process of Sheet Metal:

Fundamentally, shearing is the primary step within sheet metal preparation. It includes cutting and shaping utilizing edges and other instruments. Shearing is exceptionally critical since it will exceedingly decide the conclusion item. Shearing moreover exceedingly utilize kick the bucket and punch. It too includes shaping of breaks which is able exceedingly to decide the proliferation of the sheet working handle. The kick the bucket and the punch preparation too profoundly decide the sum of clearance that can happen of the designed metal. Shearing can exceedingly shift from 2% to 8% of the sheet metal structure. Clearance is additionally decided by the sort of metal and useful prerequisites. Essentially bigger edges require the next level of metal shearing or clearing handle. Fundamentally, the sheet shaping preparation includes plastic arrangement. Fundamentally, a plastic arrangement compresses the metal sheet over an edge and shapes a break to partition the metal structure into two.

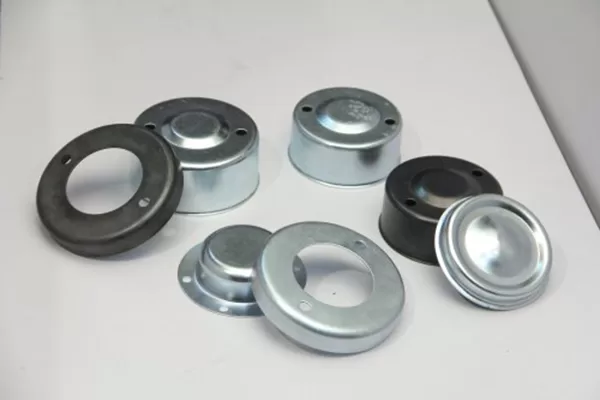

Sheet metal for truck trailer parts

The Yield point Of Sheet Metal:

The abdicate point could be a pivotal portion to look at within the sheet shaping forms. Typically basically because it shows the stretch and in case you pass the abdicate point the sheet metal is likely to create marks that can make its appearance look bad. Stretcher strains are moreover alluded to as luce band and thus within the sheet shaping forms, you ought to guarantee merely see at the abdicate point sometime recently you select the foremost suitable sheet shaping forms. Surpassing the surrender point is likely to bring out prolonged strains that will make your sheet appearance terrible.

Factors for Attaining Yield Point in Sheet Metal:

Other components just like the fabric grain measure too impact the sheet metal shaping forms. The most figure is to guarantee. Be that as it may, in case the yield point is inadvertently passed and stains are shaped, you’ll be able to expel the stains by utilizing mood rolling or skin rolling. Grain estimate too profoundly impacts the harshness or the smoothness of the metal sheet.