There are many different types of 3D printing materials and technologies that you can find in the market. You might have heard of the 3D printing machine that built the installations for Dior in Dubai, or the bioprinters that can create organs. These options are real and not in a science fiction movie.

With many 3D printers available in the market, these options presented a dilemma to entrepreneurs who are investing for their business or the researchers looking for new technologies for their institutes: which 3D printing technology is perfect for them.

We have the answer in this article. Read our comparison between two of the most popular types of 3D printing and find out which type is perfect for your project.

SLA part

What is SLA 3D Printing?

Stereolithography (SLA) was first introduced in the 1980s and was quickly used by many consumer products companies and manufacturers. It operates on photopolymers instead of filaments. These materials are light-sensitive and change their physical properties when they are exposed to light.

It also uses a laser to cut through the liquid resin and create a part in a process called photopolymerization. To say that SLA is unique is an understatement. Because of its unique printing process, it can create high-resolution parts with watertight and isotropic properties.

The polymers used in SLA are thermoset materials, which means they behave differently from thermoplastics.

- Strengths: The nature of the SLA process (laser technology) produces pinpoint accuracy that enables higher tolerance for parts with improved resolution. SLA works best for the part that requires a higher level of aesthetics.

- Weaknesses: SLA may produce parts with better aesthetics, but it sacrifices the product’s strength to achieve beauty. While there are lots of improvements on the materials used to perform better, it cannot equal the mechanical properties of nylon, ABS, and other FDM materials. If you are creating parts for functional testing, you should stick to FDM 3D Printing.

What is FDM 3D Printing?

FDM or Fused Deposition Modeling is another type of 3D printing. It is also known as fused filament fabrication and the most common 3D printing technology available in the market. The FDM printers use single or dual extruders that work on thermoplastic filaments.

The filament is loaded into the machine, where it is melted and deposited on a heated platform. It extrudes the filament with a predetermined guide path. This material cools down fast and adheres to another layer by layer to create the part.

FDM 3D printers come in a variety of sizes and capabilities. And the materials can range from plastics such as ABS, ASA, PLA, while the more advanced printers are now using nylon and carbon-filled materials. They are more durable and longer lasting.

- Strengths: What FDM 3D printing offers is better cost savings compared to SLA. It also tends to yield better results with high repeatability and strength. The FDM machines are also easy to operate and do not pose any threat when in use.

- Weaknesses: The biggest challenges when using FDM are tolerance and resolution Compared with other 3D printing technologies, they leave visible lines and slight blemishes on the finished part due to the heating and cooling of materials.

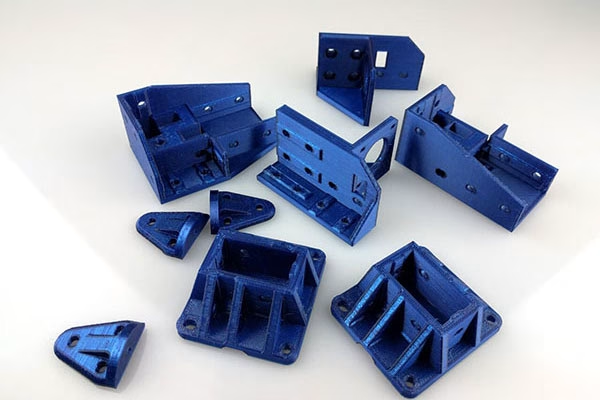

FDM 3D print parts

Conclusion

SLA and FDM 3D printing technologies have their strengths and weaknesses when it comes to their usage and specific applications. There are plenty of parameters to apply SLA or FDM technology, and our comparison does not present a complete picture. Speak to an expert to know what is better for your project.