Let’s just take a brief moment and appreciate how one plastic injection mold has transformed the whole manufacturing process making everything seamless and easier compared to traditional methods.

Well even though plastic injection molding comes with a lot of benefits, this doesn’t mean that modern manufacturing techniques don’t have its fair share of problems and issues. You’ll require a troubleshooter to fix all of these issues.

One of the major drawbacks of the injection mold technique is the fact that most technicians and engineers don’t have the specialized skills of technical know-how to operate and run the machines.

Plastic injection molders at times don’t have proper experience under their belt or the right skills as they have not been properly trained on how to handle these machines. As a result, these limitations will have huge consequences on the products which at times may not comply with the industry regulations and policies or meet the minimum expectations of the client.

For this article, we are going to briefly highlight some of the common issues of plastic injection molders enquire and the cause of every issue.

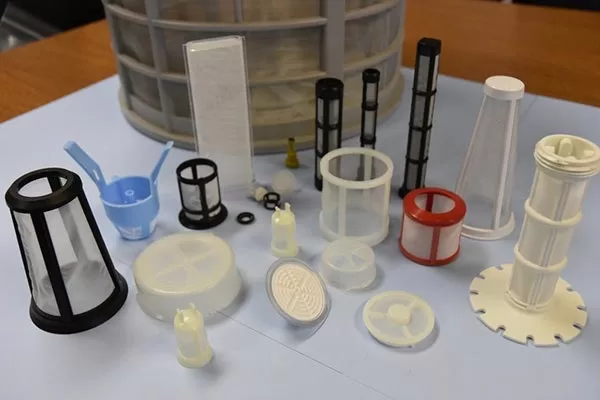

Plastic molding parts

Mold Warpage

The injection molding warpage occurs when the intended structure and shape of the molded part are gnarled during cooling. The parts that are susceptible to mold warping are the ones that can be easily twisted, bow, bend, or fold.

Some of the most common causes of injection mold warpage include:

- Insufficient injection time and pressure, this usually happens in the previous production cycle as a result of the use of the wrong or improper data used by the computer to execute tasks.

- Insufficient residence time: this is when the molten plastic is left for little or too much time inside the mold making the whole finished product looking crooked.

- Low barrel temperature: The molten plastics delivered from the barrel are not properly heated.

- The mold temperature is too low: Its when the temperature of the mold is too cold when receiving the molten plastic.

- The nozzle temperature is too low: this is especially a tricky one as it can lead to the creation of clogs in the plastic injection machine.

- Inconsistent flow rate: the injection molding machine is not delivering the right amount of molten materials for every part.

- Uneven process cycle: The delay of the manufacturing process as a result of the machine not being correctly programmed.

- Inadequate gate size: The gate delivering the molten materials don’t have the right size or specs.

- Improper gate collection: The gate that’s used to deliver the molten material is not correctly placed.

- Non-uniformity in ejection: The finished parts are not ejected the way it should.

Mold burns

The mold burns are one of the most common issues that arise with plastic injection molding, they are easily noticeable as it appears as black discolorations on the finished part. They also look rusty or brownish, they can also have small spots or streaks.

Some of the most common causes of mold burns include:

- The injection speed is a bit high

- Inconsistent resin temperature

- There is a lack of venting which makes the burn more visible

- Trapped air in the pockets and injection cavities