Every single manufacturing project has one thing in common: you need suitable materials to work with, and you need them to be as cost-effective as possible. It also helps if they have an extended lifespan and make the product you are creating lighter. This kind of research takes a lot of time, and it drains more resources you should be using in something else.

There are certain materials in the manufacturing industry that are as reliable as the sun, however. If you are working on a project that calls for extrusions, then aluminum is the way to go. We will point out why you need aluminum extrusions for your manufacturing project and why there is no other choice when it comes to reliability.

Aluminum is Versatile

Aluminum is one of the softest metals you can find to work with. It’s lightweight, and it can be molded in many shapes and take more twists and turns than a Grand Prix road. Aluminum can withstand a lot of punishment when it comes to extrusion and takes the most intricate twists without breaking.

Aluminum is Cheaper

The versatility part is on par with the costs of it. Aluminum is one of the cheapest materials out there when bought by the bulk and without extra alloys. It makes extrusion and assembly more uncomplicated and more cost-effective on the client’s end.

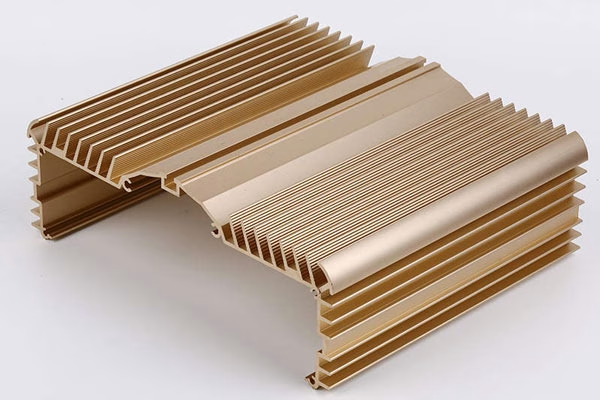

Custom aluminium extrusion parts

Aluminum’s strength-to-weight Ratio is Out of This World

Aluminum is one of the few metals that can take a lot of weight and pressure without getting much of a dent on it. It’s more durable in this regard than steel. That’s the main reason why so many vehicles are manufactured with it. It has made them lighter and faster than ever.

Is Non-Corrosive

Aluminum never gets corrosive; the oxidation effect on aluminum’s surface allows it to create a thin veiled film that protects it from the impact of the most extreme conditions.

Aluminum Can Hold High-Performance Coatings

Aluminum can withstand anodizing, high-performance coatings, and enhancers for its already powerful non-corrosive properties. Some of the most durable equipment for professional explorers can withstand extreme environments due to the extra properties that aluminum can hold.

It’s Environmentally Friendly

Do you know what the primary source of aluminum these days is? Outdated equipment that has run its course. That’s right, although bauxite is still mined in a few corners of the world, most of the aluminum used in the world comes from decommissioned planes, demolished buildings, and out-of circulation vehicles.

With such a ratio of action, it is impossible to deny the long-lasting benefits of getting aluminum for any manufacturing project. We can use the material for all sorts of extrusion projects, such as plumbing to shelves, and more than that when it comes to components for larger equipment.