Rapid prototyping is the quick creation of a physical portion, show, or gathering utilizing a three-dimensional computer helped plan. The creation of the portion, show, or get together is more often than not completed utilizing added substance fabricating, more commonly known as three-dimensional printing. Rapid prototyping utilizes specific laser melting process. Where the plan closely matches the proposed wrapped up item it is said to be a tall devotion model, as restricted to a unique devotion format, where there is a stamped contrast between the prototype and the ultimate item.

What Is the Cost of Running a Rapid Prototyping Project?

The total amount depends on a number of variables, counting volume or measure of the portion or parts being made, the surface wrap up, the materials utilized and how much post make handling is required.

Top-Notch Reasons for People to Use Rapid Prototyping:

There are a number of rapid prototyping focal points, such as being able to pick up a more total picture of how a item will see or perform within the early organize of the plan and fabricating cycle, permitting changes or changes to be executed prior within the process. The time this takes can shift from many days to a number of months, depending on the strategies used. Rapid prototyping may be an exceptionally fetched viable way to model items because it is an robotized prepare, requiring less staff to function. This handle is additionally amazingly exact, being able to utilize computer helped plan to assist diminish the sum of fabric wastage and does not require uncommon apparatuses for prototyping each modern item. Being able to act rapidly and illuminate any issues too diminishes the chance of exorbitant mistakes amid the fabricating arrangement.

Rapid prototyping makes a different originator display unused concepts to board individuals, clients or speculators so that they can get it and favor an improvement or item. This perception can too permits originators to pick up prepared criticism from clients and clients based on a real physical item instead of a concept. As rapid prototyping is an iterative handle it permits client prerequisites to be incorporated into plans cost-effectively. The method cuts out the required for redone items to be outlined from scratch whereas giving more noteworthy choice and adaptability for clients.

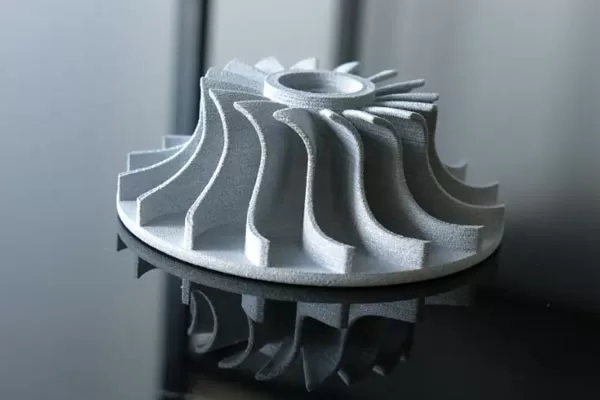

3d printing part

Quality Applications of Rapid Prototyping:

Item creators utilize this preparation for fast fabricating of agent model parts. This will help perception, plan and advancement of the fabricating prepare ahead of mass production. Originally, quick prototyping was utilized to make parts and scale models for the car industry in spite of the fact that it has since been taken up by a wide extend of applications, over different businesses such as therapeutic and aviation. Fast tooling is another application of RP, whereby a portion, such as an infusion shape plug or ultrasound sensor wedge, is made and utilized as an instrument in another prepare.

The Functioning Process of Rapid Prototyping Work:

Quick prototyping incorporates an assortment of fabricating innovations, in spite of the fact that most use layered added substance fabricating. Be that as it may, other innovations utilized for RP incorporate high-speed machining, casting, forming and extruding. Whereas added substance fabricating is the foremost common quick prototyping prepare, other more customary forms can also be utilized to make models. These forms incorporate: Compressive – whereby a semi-solid or fluid fabric is constrained into the required shape some time recently being cemented, such as with casting, compressive sintering or shaping. Subtractive – whereby a piece of fabric is carved to create the specified shape utilizing processing, crushing or turning.

Selective Laser Sintering and Material Jetting of Rapid Prototyping:

This reasonable, easy-to-use prepare can be found in most non-industrial desktop 3D printers. It employs a spool of thermoplastic fiber which is dissolved interior a printing spout barrel some time recently the coming about fluid plastic is laid down layer-by-layer according to a computer statement program. Whereas the early comes about for the most part had destitute determination and were powerless, this handle is moving forward quickly and is quick and cheap, making it perfect for item improvement. Utilized for both metal and plastic prototyping, SLS employments a powder bed to construct a model one layer at a time employing a laser to warm and sinter the powdered fabric. Be that as it may, the strength of the parts isn’t as great as with SLA, whereas the surface of the wrapped up item is as a rule unpleasant and may require auxiliary work to wrap up.