After manufacturing your parts and products, the next step should be how to market your products faster and quicker. Well, we can confidently say that rapid prototyping will enable you to achieve all your goals faster.

Among the different rapid prototyping techniques, prototype tooling is perhaps the best manufacturing technique that will get the job done. First and foremost, before delving any deeper, we first need to look at the definition of prototype tooling.

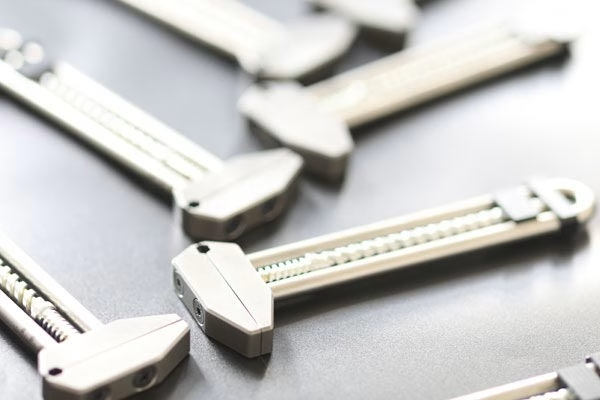

Rapid tooling parts

Definition of prototype tooling?

Prototype tooling can be commonly referred to as soft tooling or rapid tooling. The basic concept of these manufacturing techniques is like injection mold tooling which allows the production of parts and products quickly and cost-effectively.

This will enable for authentication and testing of parts before full production can be rolled out. So, it’s vital that you first understand and comprehend the whole manufacturing procedure before you can fully use it.

Prototype tooling is regarded as one of the most effective and efficient manufacturing techniques that have proven to be a hit with most clients and manufacturers. When it comes to the authentication and testing of parts, it’s vital for product development. It’s worth pointing out that other notable prototyping techniques are much cheaper and more cost-effective such as vacuum casting, CNC machining, 3D printing just to mention a few.

The tooling option that comes with these prototyping options is its capability to analyze and use production-grade materials thus giving you a clear picture of how different components and parts are used in these applications.

These techniques, also allows you to test whether the raw materials are compatible with these production and manufacturing techniques. Having this full information in mind, it can be quite easy to determine and factor in if there are design changes to be factored in during the latter stages of production. It’s for these specific reasons that prototype tooling plays a vital role when it comes to ensuring the client’s specifications and requirements are met.

Rapid tooling is also very vital as it checks all the parameters of the whole production process and ensures you get parts that fit properly and perform as required. This is quite important for engineers and designers as now they can be able to identify potential defects and flaws and factor in redesigns and other measures to mitigate these types of issues onto the final part.

Important features to consider

When it comes to the benefits that come with prototype tooling, it will be dependent on a wide range of factors such as size, consistency, accuracy as well as materials just to mention a few. First and foremost, you’ll need to ensure that your mold is robust enough to able to withstand the rigors and pressures of the injection molding process or it might not survive at all.

The edges of the mold must also be very smooth enough to allow for clean ejection, prototype tooling is an efficient method that will overhaul your manufacturing technique and take it to the next level.