Rapid tooling is also commonly known as prototype tooling, its applications can be both used for prototype or soft mold tooling. Additionally, the injection mold technique is sued to produced parts and products quickly and efficiently.

In a manufacturing sense, the injection molding procedure is used to create large quantities quickly and affordably. Aside from that, Rapid tooling allows for testing and validation of the produced parts highlighting their functionality and viability.

Rapid tooling produces high-grade materials, this will give you a much clearer picture of how your final product will look and act like in final applications. Rapid tooling comes with plenty of benefits to different manufacturing fields. With rapid tooling, you will get different favorable circumstances that will prove beneficial to your business.

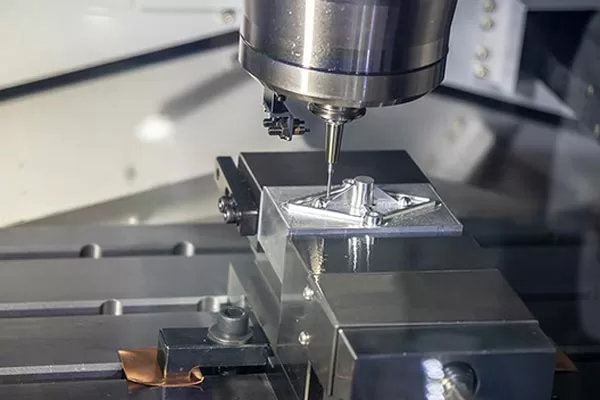

Rapid aluminium tooling

Opening more doors for innovation

One of the most promising features of rapid tooling is the fact that it opens up more doors for innovation and improvement. This will present new opportunities for advancement by eliminating all the limitations that come with traditional/conventional prototyping.

Conventional tooling requires the manual creation of prototypes and the physical segments with enough resistance. As for Rapid tooling, engineers and designers can make model designs using complex surfaces and shapes which would have been otherwise impossible using regular tooling or prototyping.

Enhanced efficiency

Rapid tooling significantly reduces the times when it comes to the creation of prototypes, molds, or devices for the demonstration to potential clients or investors.

The time between design conception and prototype production has been reduced providing you with more time to examine your product and point out potential flaws and defects which can be rectified before full-production commences.

The outcome is the production of an identical product to the original design which can be tested for the ease of use, execution, structure, and highlights. Rapid tooling is an automated process, this allows the engineers to tweak the designs accommodating both the clients’ and manufacturers’ needs.

As a result of an efficient production process, your products can get to the market faster giving you an edge over your competitors. Your competitors won’t have a choice but keep up with your speed and efficiency ensuring you are always one step ahead of the pack.

Affordable and cash saving

Another important element of the rapid tooling element is its cash saving feature. In this type of production technique, parts and products are formed using infusion which essentially means that the product can be used for effect and stress testing.

For example, let’s say you pinpoint the feeble lines and territories due to weld lines or territories as a result of shaping procedures that causes contraction or distortion.

With such crucial information, you will be able to effectively plan yourself and decide whether the rapid tooling procedure is going to benefit or a loss-making project.

There are plenty of reasons why you should choose the rapid tooling production technique, it’s a quick and modest technique that allows you to create parts faster and cheaply.