CNC Machining has become popular in the manufacturing industries because of its advantages. With the CNC machine, you can do milling, turning, prototyping, drilling, and other types of machining. You can do these techniques within a short time easily.

The CNC machine assures precision, but it requires proper inputs when it comes to materials, dimensions, and other information. Choosing the right material is a must to achieve the quality you need. The machine is compatible with a wide array of materials like metals, plastics, semiconductors, and others.

So, to help you choose the right material, we have written this guide. It is one of the secrets for effective CNC machining.

What to Consider When Choosing the Right Material

Since the CNC machine can handle both hard and soft materials, it is much easier for you to decide which material will work best for your project. Listed below are some of the factors you need to consider when choosing the material.

Purpose

You need to identify what is the company’s purpose of developing the component being machined. The process is applied to different industries like aeronautical, electronic, mechanical, automobile, and others. The use of a machined part will help you decide intelligently.

Also, it is vital to determine if the part will have several uses or not. For instance, the Aerospace industry needs lightweight but durable material for production. Thus, the metal may not be the material of choice for aerospace, but composite materials can be.

Operational Environment

Sometimes the machine is exposed to certain chemicals, high-temperature air, moisture, and others. So, it is essential to consider the operational environment before choosing the material. For example, if the CNC machined part is being utilized in equipment used in an area near the water or structure with moisture, then it will get easily corrode. In this case, you should use plastic or steel as your material in CNC machining.

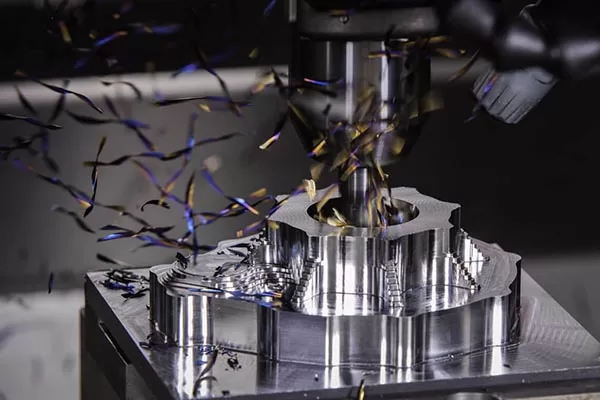

Precision CNC machining

Stress and Strain

The parts being manufactured can be exposed to various operational stress and strain. In these cases, it is essential to select a material that can withstand the stress and tension. Suggested material for this kind of condition is a metal alloy that can resist pressure and can bend easily.

For CNC machining under high stress, it is best to use heavy material. But, for weight-sensitive application, lighter material is suggested as it has an impressive bend and cracks resistance.

Stability and Tolerance

Industries like aerospace require accurate dimensioning as well as stability in parts. In this case, you need a material with the least deformation factor. Higher machinability material is necessary to make sure it can provide accurate dimensional stability.

Final Thoughts

It is clear that choosing the right material before subjecting it to CNC machining is vital. The process is a precise and purpose centered technique that should be carried out by experts for your desired outcomes. Knowledge about the CNC is essential so you can create an accurate prototype for the part being manufactured. It reduces errors, cost, and effort.