When it comes to the design of the final product using plastic injection molding, the main objective is to always create a near-perfect design that works at a minimal cost. To achieve this goal, there are always different steps involved.

Due to technological advancements, we have noticed that plastics have the same properties as metals something; a fact which was unheard of a few years ago. High-quality and performing plastics have the same durability as metals. Due to such strengths, plastic injection molding products are used in different applications such as aerospace, plumbing, replacement of medical parts from plastics to metals.

In this post, we are going to show you how you can improve on your plastic injection molding process.

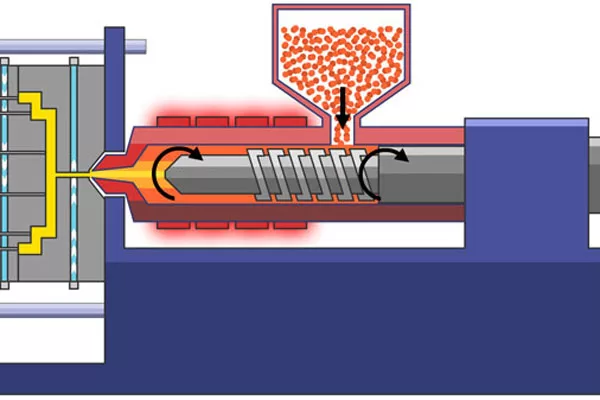

Injection molding process

Choosing the correct tooling

Plastic injection molding goes hand-in-hand with plastic injection molding, when you are looking for the production of over a million tools; the molds are primarily made of steel. Creating these types of molds take a lot of time and are usually expensive. But there are more advantages of steel than just high-volume production

One of the major benefits of steel tooling is the fact that it can hold more cavities which essentially means that more parts can be created per every shot. It also can handle complex and intricate geometries as well as work on different surface finishing.

As manufacturers, you will have a wide variety of ways to produce molds, 3D printing is one of those methods. 3D printing is a relatively affordable method of creating the mold, the only drawback is the molds will have rough finishing thus it might require further finishing process to smoothen everything out. 3D printing does not have the capacity of holding more than 100 shots, so it’s a bit limited allowing the molds to deteriorate with time.

One tooling method that is commonly used is aluminum tooling, although doesn’t produce the same volume as steel; it suitable for 10,000-50,000 shots. Sometimes it can also reach up to 100,000 shots. To enhance the longevity of the aluminum tool, optimizing the design will come in handy.

Choosing the right material

Another vital factor that will contribute to the success of your plastic injection molding project is choosing the right material. To do so, you will first need to determine the mechanical properties of these materials.

Some of the most important information that you need to ask yourself is the weight that it will support, transparency, and the temperatures it will be subjected to. With the above data, you’ll be able to narrow down some of the best materials that should be used.

Some of the widely used thermoplastic in plastic injection molding include:

- ABS (Acrylonitrile butadiene styrene) – This material can work on numerous parts and products, Not only is it sturdy and robust, but it also has a glossy finishing. One of the major benefits of ABS is it can be painted but the drawback is it has weak UV and chemical resistance.

- PP (Polypropylene)- Its an affordable plastic that is used to manufacture a wide variety of consumer products. It has impressive properties such as stiffness, clarity, and heat resistance.