The day and age of the internet have truly changed everything, well it may sound like a cliche but it’s true when it comes to the manufacturing world. The changing trends in technology and the internet has significantly improved the way manufacturing is done.

The secrets of every manufacturing sector are out in the open providing an opportunity for everybody to understand, see, and learn. Most manufacturers always want to stay ahead of the curve, that’s why they are always on the look-out for new innovative ideas and technology to stave off competition.

This is not always the same with workshops that treasure their tools of the trade and want to conceal everything even from their clients. Outsourcing has been the biggest trend of the 21st century as many people want to cut down on cost as well as boost their economies of scale.

Not only does outsourcing take a lot of things off their plate but enables them to concentrate on their production line. Any prototype, part, and product created by plastic injection molding tech can be used by workshops using state-of-the-art technology using high-quality raw materials.

Once you’ve figured out all the logistics of the manufacturer, you can now become a virtual producer. One of the trickiestthings about becoming a virtual manufacturer is finding the right partner to take your project forward.

Well, this is easier said and done, you’ll find workshops offering plastic injection molding services that are the same as partnerships but in the long run, they won’t offer genuine services as advertised.

Your partner should be able to handle everything from the word go, from the creation of the CAD files to the creation of the end-product. They should be able to use the best raw-materials providing high-quality products.

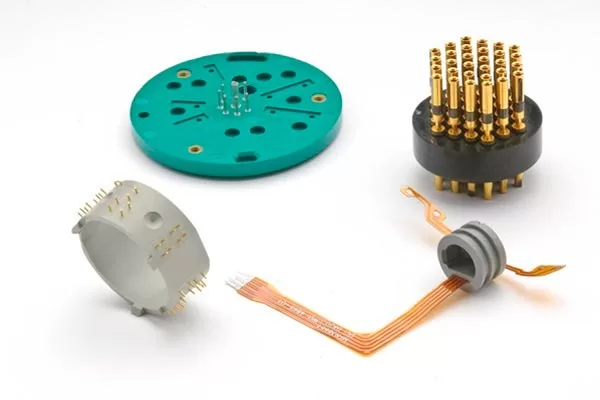

Insert molding parts

The secrets of virtual manufacturing- Step by Step procedure

This can sound confusing at first, but diversifying the manufacturing industry can make everything easy and seamless for entrepreneurs. Knowing the ins and out of the logistic process is very important as it will give you all the insights of your production project allowing you to monitor and control everything.

For the success of virtual manufacturing, you should choose a workshop that has a steady operation, this will enable you to oversee everything, you will have a say when it comes to altering original designs if something is not working out as expected.

Always remember that virtual manufacturing will be heavily reliant on your ability. So, do a background check on your manufacturer or workshop. The internet will give you the control that you need to ensure your project is a huge success.

The value of the virtual plastic injection molding process

Once you’ve mastered all the logistics about your business, then you will have all the tools to be a successful entrepreneur with a respectable brand. Invest a lot of time and money, this means getting to know their manufacturer and the whole production team.

This will not only show you good business acumen as well as give you firsthand information about the whole operation.