In a world where mass production often reigns supreme, churning out endless copies of identical products, there’s a growing desire for something different, something unique. Customization is becoming the new king, and low-volume manufacturing is its royal court. This approach empowers businesses to break free from the mold, crafting bespoke products that cater to individual needs and desires. It’s like a tailor crafting a custom suit, ensuring the perfect fit for every customer.

Low-volume manufacturing isn’t just about creating unique products; it’s about unlocking a world of possibilities. It’s about agility, innovation, and responding to the ever-changing demands of the market with the grace of a dancer. Let’s explore why customization is taking center stage and how low-volume manufacturing is making it happen.

1. Meeting Unique Customer Needs

In today’s world, customers crave individuality. They want products that reflect their unique tastes, preferences, and needs. Offering tailored solutions is no longer a luxury; it’s an expectation. Low-volume manufacturing allows businesses to step up to this challenge, producing highly customized products that resonate with end-users on a personal level. From personalized medical devices that fit like a glove to limited-edition consumer goods that make a statement, this approach ensures that products not only meet needs but also capture hearts.

Imagine a car enthusiast who wants a vehicle that’s as unique as their fingerprint. Low-volume manufacturing makes this dream a reality, allowing for the production of bespoke parts or even entire vehicles tailored to a customer’s exact specifications. Similarly, in the fashion industry, where trends change like the wind, low-volume manufacturing supports the creation of exclusive designs that cater to niche markets and capture the zeitgeist. Customization enhances the user experience, increases customer satisfaction, and builds brand loyalty that lasts.

2. Faster Time-to-Market for Prototypes

In the fast-paced world of product development, speed is of the essence. Low-volume manufacturing is a crucial tool in this race, allowing businesses to rapidly produce prototypes or small production runs. It’s like a sculptor creating a clay model, testing and refining the design before committing to the final masterpiece.

This iterative process allows businesses to test new designs, gather valuable user feedback, and refine their products before diving headfirst into mass production. It’s a safety net that reduces the risk of costly errors and ensures that the final product hits the bullseye of market expectations. The ability to move quickly from concept to prototype gives companies a competitive edge, allowing them to respond to emerging trends and consumer demands with the agility of a cheetah.

3. Reducing Waste and Costs

Unlike high-volume manufacturing, which often requires significant upfront investment in molds, tooling, and mountains of materials, low-volume manufacturing is a lean and efficient approach for smaller production needs. By producing only the exact quantity required, businesses minimize waste and avoid the dreaded curse of overproduction. It’s like a chef preparing a meal, using only the necessary ingredients to create a culinary masterpiece.

This efficiency not only reduces costs but also aligns with the growing focus on sustainability. Many industries, from consumer electronics to healthcare, are embracing low-volume manufacturing to create eco-friendly solutions that minimize their environmental impact. It’s a win-win situation, benefiting both the bottom line and the planet.

4. Supporting Innovation and Market Testing

Customization thrives on creativity, and low-volume manufacturing is the perfect playground for innovation to flourish. By producing small batches of experimental designs, businesses can explore new ideas, push boundaries, and challenge the status quo without the risk of large-scale failure. It’s like a scientist conducting experiments, testing hypotheses before making groundbreaking discoveries.

This approach is particularly valuable in emerging industries such as electric vehicles (EVs) and renewable energy, where rapid innovation is the key to success. It also allows companies to test the market viability of new products, gathering valuable data and insights before making critical decisions about scaling production.

5. Flexibility Across Industries

Low-volume manufacturing is a versatile tool that can be applied across a diverse range of industries, each benefiting from its unique advantages:

- Medical Devices: Imagine creating tailored implants, prosthetics, and instruments that perfectly match the needs of individual patients. Low-volume manufacturing makes this possible, improving patient outcomes and enhancing quality of life.

- Aerospace: In the aerospace industry, where precision and reliability are paramount, low-volume manufacturing enables the creation of custom components for aircraft and spacecraft, ensuring that every part meets the highest standards of performance.

- Consumer Electronics: From limited-edition devices that capture the imagination to accessories with unique features or designs, low-volume manufacturing allows consumer electronics companies to cater to niche markets and create products that stand out from the crowd.

- Packaging: Custom packaging solutions that align with branding and marketing goals can make a product truly shine. Low-volume manufacturing empowers businesses to create packaging that not only protects but also elevates the product within.

Each of these industries benefits from the ability to produce high-quality, customized products without the commitment and risk associated with mass production. It’s a flexible approach that adapts to the unique needs of each industry.

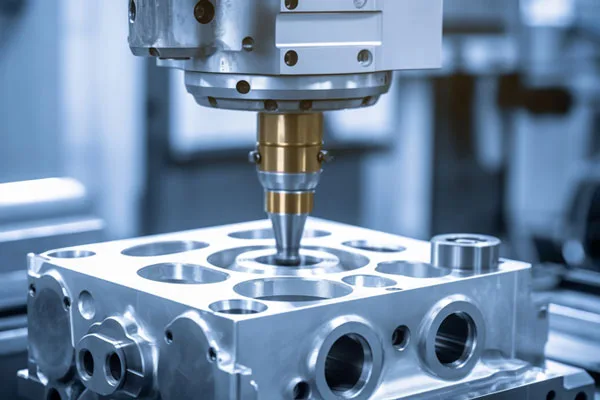

CNC manufacturing

Key Technologies Driving Low-Volume Manufacturing

Several advanced manufacturing technologies have emerged as the driving forces behind low-volume production, making it more accessible and efficient than ever before:

- 3D Printing/Additive Manufacturing: This technology is ideal for creating prototypes and complex geometries quickly and cost-effectively. It’s like a magic wand, conjuring up physical objects from digital designs.

- CNC Machining: CNC machining offers high precision for producing custom parts in small quantities. It’s a workhorse for creating intricate components with tight tolerances.

- Injection Molding with Rapid Tooling: This approach enables fast and flexible production of plastic components, bridging the gap between prototyping and mass production.

- Sheet Metal Fabrication: Tailored to creating durable, custom metal parts for industrial applications, sheet metal fabrication offers a robust solution for low-volume production.

These technologies reduce lead times, lower costs, and enhance customization capabilities, making low-volume manufacturing a viable option for businesses of all sizes, from nimble startups to established giants.

Real-World Applications of Low-Volume Manufacturing

Low-volume manufacturing is making a real-world impact across various sectors:

- Startups and Entrepreneurs: For startups with limited resources and big dreams, low-volume manufacturing is a lifeline. It allows them to bring their innovative ideas to life without the financial burden of mass production. By producing small runs, they can test the market, gather valuable feedback, and refine their offerings before scaling up.

- Niche Markets: Brands targeting niche markets with unique products rely on low-volume manufacturing to cater to specific tastes or needs. This approach ensures they can meet the expectations of their discerning customers without overcommitting resources.

- Rapid Prototyping for Tech Companies: In the fast-paced world of technology, where innovation is a constant race, tech companies use low-volume manufacturing to iterate quickly on new designs, staying ahead of competitors and addressing customer needs with lightning speed.

The Future of Low-Volume Manufacturing

As the demand for personalization and sustainability continues to grow, low-volume manufacturing is poised to become even more prominent. With advances in automation, AI, and additive manufacturing, the ability to produce customized, high-quality products in small quantities will become even more efficient and accessible.

Businesses that embrace this approach can expect to remain agile, meet the diverse needs of their customers, and lead the charge in innovation—all while reducing costs and minimizing waste. It’s a future where customization reigns supreme, and low-volume manufacturing is the key to unlocking its full potential.

Conclusion

Low-volume manufacturing is redefining the very essence of production, placing customization at the forefront. In a world where consumers demand products that reflect their unique preferences and values, this approach empowers businesses to deliver tailored solutions with efficiency and finesse.

By leveraging advanced technologies and embracing the flexibility of low-volume manufacturing, companies can innovate, scale intelligently, and remain competitive in an ever-changing market. Customization is king, and with low-volume manufacturing, businesses can claim their rightful place on the throne.