The history of plastic began in the late nineteenth century when celluloid, the first man made plastic was invented. Among the first items created in plastic was the comb. Before then, the piece was made of different materials available to man – from bone to iron to wood. However, the endless possibilities faded with plastic.

The transformation of the comb mirrored how our lives have been transformed by plastic. It allows us to create things without the constraints of material choices and supplies. The arrival of plastic and the plastic injection molding process has allowed manufacturers to create new products for people who can afford them.

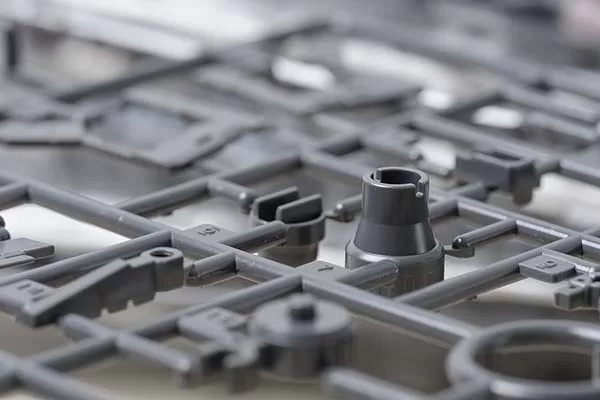

Plastic parts

History of Plastic and Injection Molding Machines

Plastic is a substance that has affected our lives. The word comes from the Greek verb plassein, which means “to shape or mold.” Quite fitting for plastic, as it can be shaped into anything thanks to its structure of long, flexing chains of atoms or small molecules bonded in a repeating manner to form a gigantic molecule.

The earliest raw materials used for plastic are plant celluloid, but most of today’s plastics are made of hydrocarbon molecules – with packets of hydrogen and carbon derived from refining natural gas and oil.

Plastic injection molding is the process responsible for creating plastic products across all industries such as automotive, electronic, home appliance, houseware, medical industry, and so on. The products range from buttons to parts used in aerospace.

It is a truly versatile and incredibly useful process and has paved the way for more modern design and invention.

Plastic injection molding was first used in 1868 when billiard ball maker Phelan and Collander asked John Wesley Hyatt to make billiard balls. During the project, John and his brother Isaiah invented the injection molding machine. It was a primitive machine but fitted its purpose. The machine was made of a basic plunger to inject the plastic into a mold through a heated cylinder.

The technology was picked up in 1946 by James Henry. His injection molding machine was built with an auger to replace the plunger in Hyatt’s design. The auger, this time, was placed in the cylinder and mixed the material before pushing it forward and injecting it into the mold. This became the standard for all injection molding machines.

Modern Injection Molding Machines

Today, the injection molding machines are much sleeker, but the technology itself has not changed. Although computer technology plays a bigger role to achieve more precision in the injection molding process, the principle behind the machine remains the same. It only made the machine more efficient, creating more products for the market today.

When you look at any home or shop, it is not hard to find at least one thing created with injection molding. This shows how plastic and plastic injection molding has become an integral part of today’s manufacturing industry,

Currently, the plastic injection molding sector in China generates billions of dollars every year, with million metric tons in production. Nice Rapid is one of the most revolutionary plastic manufacturers in the country catering to overseas clients. The company specializes in all kinds of plastic injection molding. Call them for more details.