The compression molding process is the simplest fabrication among the lot. The whole process is not complicated at all. As it involves inserting the material into the mold, closing it, applying pressure and heat, curing and finally opening the mold and removing the part.

On top of being simple, the whole process is fully automated and has high repeatability. It may sound not so complicated but before deciding on choosing this manufacturing method, you have to know all the facts about this process first.

We made it easy for you. This article will give you all the essential facts you should know about compression molding.

What is Compression Molding?

Compression molding is the process use of two advantages of the molding techniques, the conventional injection molding, and compression. There are two stages in this process. First, the melted polymer is injected into the mold to partially fill it. This mold is partially open for the second stage.

The next stage is the compression phase. In the compression phase, the heated mold is exposed to pressure to set. When the material has set, the final product will be removed from the cavity.

What makes compression molding unique is it uses the power of pressure and heat. The addition of these two elements in the process changes the characteristics of the final product. The heat helps the material and the mold to expand, but when you add pressure into the mix, it makes the process more effective.

The Compression Molding Process

In compression molding, the material and the mold are heated. Once it has reached the desired temperature, this heated material is poured into the mold cavity. With the liquid material in the mold, it will be closed using the plug on top.

The machine will exert the right amount of pressure on the material so that it could fill even the smallest spaces in the cavity. A compression molding process can have a pressure between 1,000 to 2,000 pressure per square inch (psi). The intense pressure and heat will force the material to cover all the spaces in the cavity.

Once the material and the cavity cools, the part will then be removed from the mold. You may find many other compression molding techniques, but the entire process is the same. A heated polymer material is poured into a heated mold and after which the mold cavity is exposed to pressure.

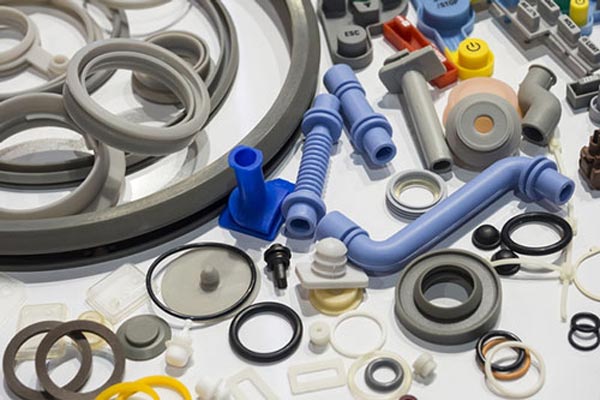

Compression molding parts

What Should You Consider In Compression Molding

When using compression molding as a manufacturing technique, the following factors should be considered:

- Quantity thermoset plastics or thermoplastics

- Amount of heat

- Type of heating method

- The mold designs

- Amount of pressure

There are two types of materials used in compression molding: thermosets and thermoplastic. These materials are unique to this process. The thermoset plastics refer to pliable plastics, an example is a hydraulic seal that will not change its shape once heated and set.

Thermoplastics, on the other hand, can harden as a result of the application of heat, turning it to a liquid state. This type of material can be heated and cooled repeatedly without changing its integrity.

The temperature applied to the mold cavity differs with each product. While the time it takes to complete the process is dependent on the material and thickness of the part. What is important is to ensure that the material was able to fill in the crevices in the mold to perfect the product.

Benefits of Compression Molding Process

The main use of compression molding is to create strong and durable products. Exposing polymer or plastic material to pressure will make its products durable and strong. Although injection molding can also make strong products, it is not as strong and sturdy as the one produced by compression mold.

Aside from creating durable products, this manufacturing process can also create products with complex shapes that cannot be made with other molding techniques. This is because the applied pressure on the molding cavity will force the melted material to all the crevices in the cavity.

What Does the Future Hold for Compression Molding

Like other manufacturing techniques that use different raw materials, the demand for compression molding will remain. The demand for products made from polyurethane and hydraulic seals will never cease and its application will spread throughout other industries.

With the advent of computers and technology, it will influence how the compression molding process works going forward. There will be more automation in the process that requires less manual labor. The idea of having a fully automated assembly line that will operate all the steps in compression molding is not far-fetched after all.

Conclusion

The compression molding process offers a different technique. With the use of two components, heat and pressure, it can create strong and durable products that have multiple applications in many industries. Although it is still labor-intensive at this stage, the future of the compression molding process is geared more towards automation.