Sheet metal is no doubt the most highly adaptable building material in the manufacturing industry. It is for this reason that it has found its rightful place in the industrial age. Different materials can be used in sheet metal fabrication. It can be steel, brass, copper, aluminum, nickel, tin, titanium, and many others.

The thickness of sheet metal may vary depending on its use. It can be broken into two: heavy plate or thin gauge. There are plenty of industries that rely on the durability and versatility of sheet metal. Hence, you can find them in appliance manufacturing, industrial furniture, types of machinery, transportation, and consumer electronics.

What is Sheet Metal Fabrication?

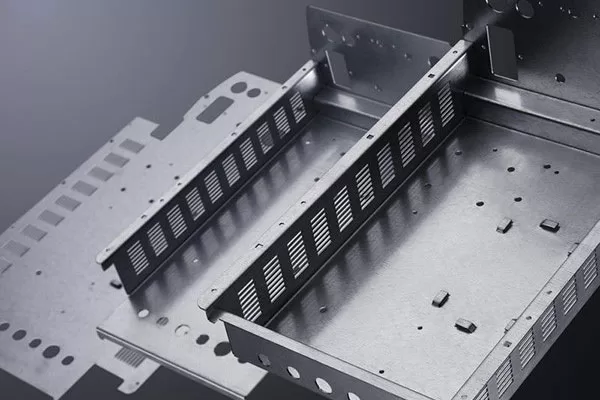

This manufacturing technique is designed to turn sheet metal into functional parts. Traditional sheet metal fabrication is tedious and requires hard work. Thanks to the advancement of technology, fabrication has become automated and the use of CAD programs has made it easier to design sheet metal.

Sheet metal fabricated components

What to Consider When Choosing Sheet Metal Fabrication

There are five factors that you should consider before deciding to use sheet metal fabrication. Here they are:

- Purpose of the Sheet Metal. There are plenty of things that you can do with sheet metal. Like any other technology, it is constantly evolving. The materials, process, equipment, and tooling are becoming specialized to improve the speed of production and design process.

- Fabrication Technique. Sheet metals are flat at the beginning but can be fabricated into different forms depending on the requirements. It can be processed using different techniques like stamping, spinning, hydroforming, or deep drawing.

- Types of Sheet Metals. Some many different alloys and metals can be used in manufacturing parts from sheet metal. The choice of the material to use depends largely on the final application of the metal sheets. Some of the qualities you should consider include weldability, formability, strength, weight, corrosion resistance, and cost.

- Design Considerations. Sheet metal fabrication is cost-effective when the right tools are used instead of using costly custom ones. If it is hard to make a single part, then engineers consider riveting or welding the part together with the use of standard tools. Another quality of sheet metal that is beneficial is high tolerances. When manufacturing sheet metals, you need detailed tolerance specifications to choose the right machine.

- Finishing. The last factor that you need to know before deciding on the metal sheet fabrication. The technique depends on the type of material, and it is a means to protect the metal from corrosion and rust. Finishing is also applied to enhance its appearance.

Conclusion

In sheet metal fabrication, the first step is choosing the material. It will depend on the function of the part. The selection of the material and the gauge are two of the critical steps in balancing other features of the sheet metal like weight, strength, and cost.

It is easy to outsource sheet metal fabrication but selecting the right partner can help to bridge the gap between designing and fabrication. Look for a partner who is willing to collaborate with you and has a proven track record of producing high-quality parts.