Rapid Tooling can be defined as a combination of traditional tooling art and rapid prototyping techniques. It is a quick and effective way of making molds through a simple CAD file. Owing to its many advantages, various manufacturing businesses have adopted rapid tooling for creating molds. There is no need to go through developmental cycles and this helps save a lot of time. It proves essential in industries that need to produce goods in a huge quantity within a short span.

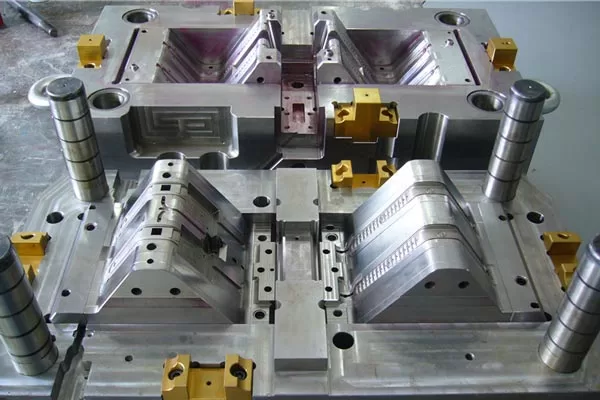

Rapid tooling machine

How Does It Benefit Your Business?

Industries such as automobile, healthcare, and others require mass production of goods to tackle the surge in demand. Many sectors have added rapid tooling to the manufacturing process due to the following uses:

- The cost of production reduces greatly when rapid tooling technique is employed. There are no developmental cycles and many products can be produced from a single mold.

- Tools or products that are made through rapid toolingcan be launched quickly. They can be tested quickly and produced at a faster rate.

- Except for the cost of production, the time of production is also reduced. If there is any surge in demand, it can easily be met as goods or tools can be produced at a faster rate.

- Rapid tooling is a versatile technique. It can be used in different industries to create different types of molds. Customized molds can be also be made through this technique.

- Troubleshooting problems is easier. Moreover, the job of developing molds can be outsourced to further help costs and time.

Why Should You Consider Adopting Rapid Tooling?

As the abovementioned advantage states, rapid tooling is not limited to a single industry. It can be used to create molds for various parts, tools, and so forth. It uses injection molding to create molds for complex structures. They products produced through such molds are a great copy of the original product. Though, they might not have the same finish or quality, they fulfill the required purpose and leave the end-users satisfied.

Molds are of different types, hard and soft. Depending upon the product to be replicated the type of mold changes. The soft ones are usually made up of polyurethane and the hard ones are made up of steel. The molds are also available in different colors. Your business can choose to outsource the job of rapid tooling to experts. They will produce molds in a short span while your business can focus on other aspects of manufacturing.

Choose Rapid Tooling for Cheaper and Quicker Production

Indeed, rapid tooling proves better than conventional production practices. Your business can save a lot of time and cut on expenditure with the help of this technique. A single mold could produce up to 20 products. Without rapid tooling, mass production in a short span is almost impossible to reach.

With the option of hiring another firm to produce molds, the process becomes easier. Your business does not need to create a new department or hire new staff. Make use of rapid tooling to increase production and boost business revenue.