by Nice Rapid | Jul 5, 2021

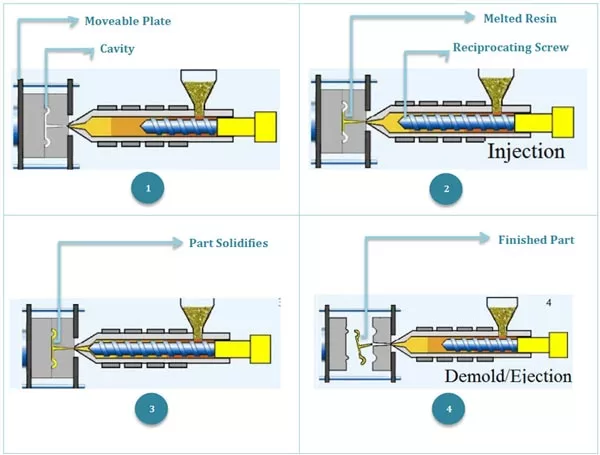

5 Most Common Resins Used in Plastic Injection Molding One of the reasons Plastic Injection Molding is so prevalent among the manufacturing processes is due to it offers a wide range of materials selection. This allows product designers and engineers able to create...

by Nice Rapid | Jun 16, 2021

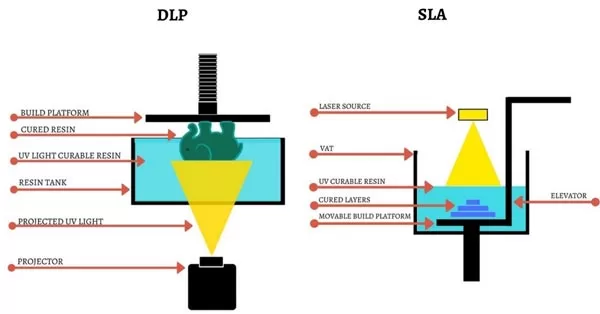

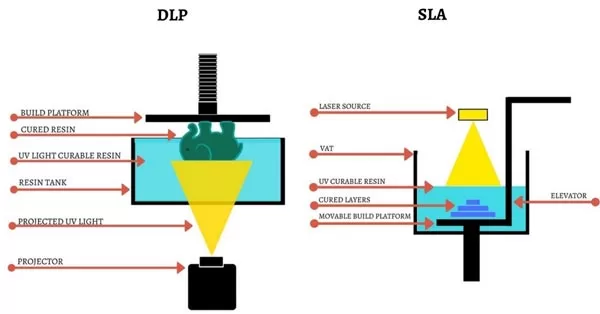

Rapid Prototyping with SLA What is Stereolithography (SLA) Stereolithography(SLA) is the most widely used rapid prototyping technique and it produces the finest surface finish and dimensional accuracy in comparison to other additive manufacturing (AM) or 3D printing...

by Nice Rapid | May 31, 2021

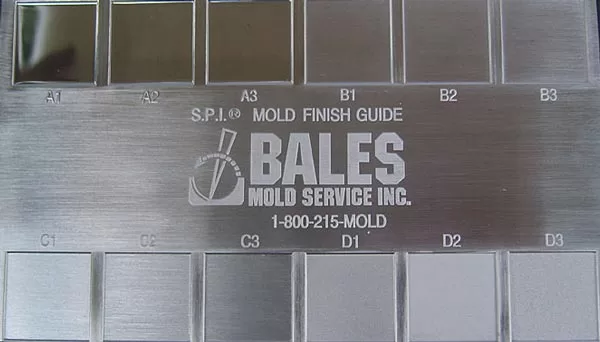

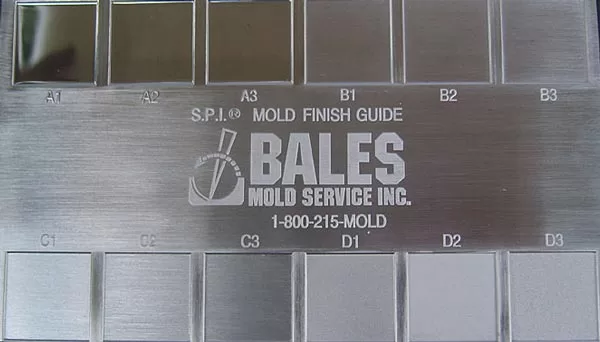

Plastic Injection Molding Surface Finishes Plastic injection molded parts can be surface finished from matte to highly polished. The higher requirement on the surface finish of the part, the longer effort and time spent during the production of the mold, hence it...

by Nice Rapid | May 18, 2021

7 Additive Manufacturing Technologies & The Materials Additive Manufacturing (AM) or most commonly known as 3D printing is defined as a process of joining materials layer by layer to form a part from 3D CAD model as opposed to subtractive and formative...

by Nice Rapid | May 8, 2021

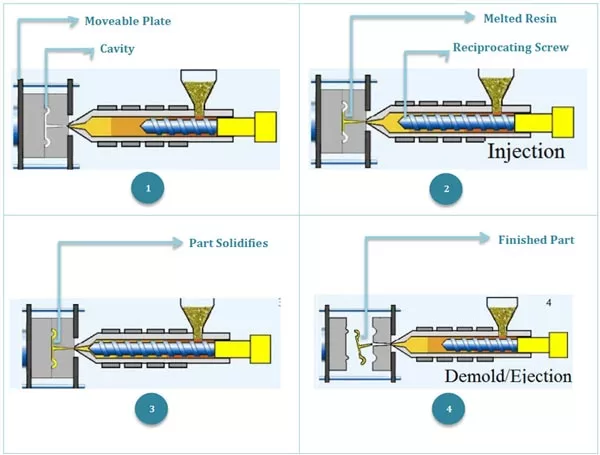

What is Plastic Injection Molding? The Basics of Plastic Injection Molding Plastic Injection Molding is a manufacturing method to obtain plastic molded product by injecting molten plastic resin into a mold, the resin then cools below its melting temperature and...