by Nice Rapid | Apr 29, 2022

8 Important Reasons Why You Need Prototypes There are several steps in building a product before pushing it for mass production. In each stage, the main goal is to have a product for specific target customers and solve their pain points. To evaluate if this product...

by Nice Rapid | Apr 24, 2022

The Impact of Aluminum Extrusion Process on the Environment The industrial revolution might have been ages ago, but we can still feel its impact on the environment. We have pushed the limits, and there is obvious stress on the basic life support systems. Its...

by Nice Rapid | Dec 28, 2021

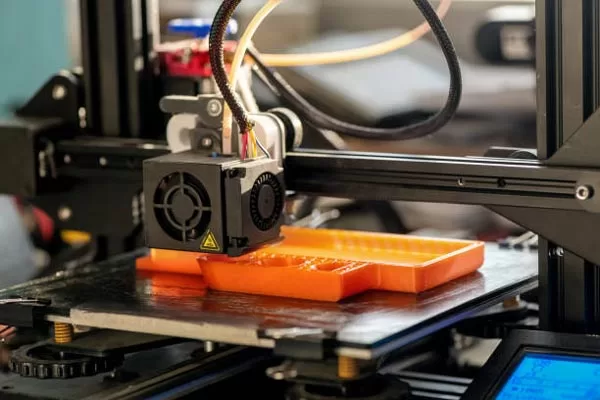

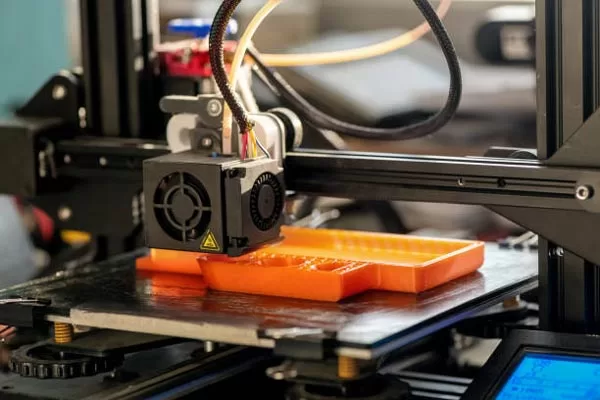

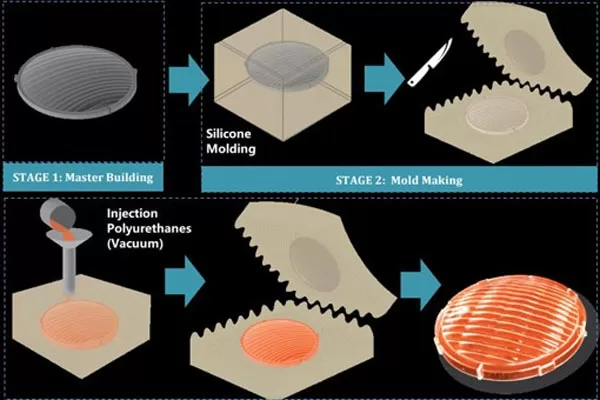

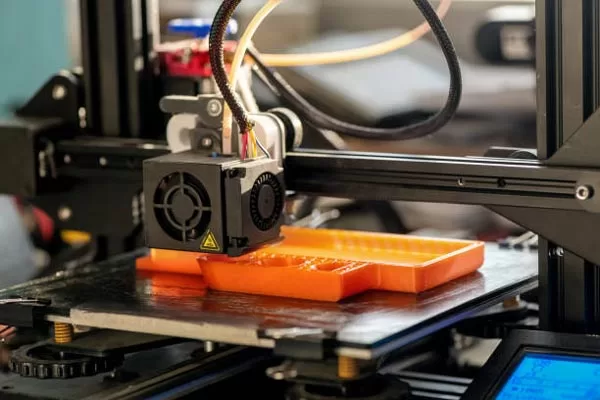

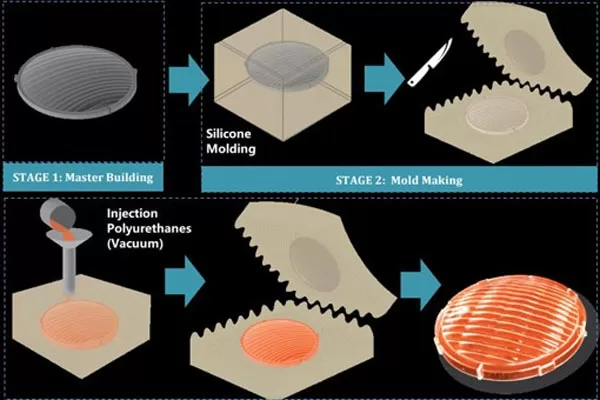

What is Vacuum Casting? Introduction Vacuum Casting is a copying method used to mold thermosetting polyurethane (PU) for fast production of prototypes or end-use products. There are many different types of PU, which makes this process suitable for the majority of...

by Nice Rapid | Nov 9, 2021

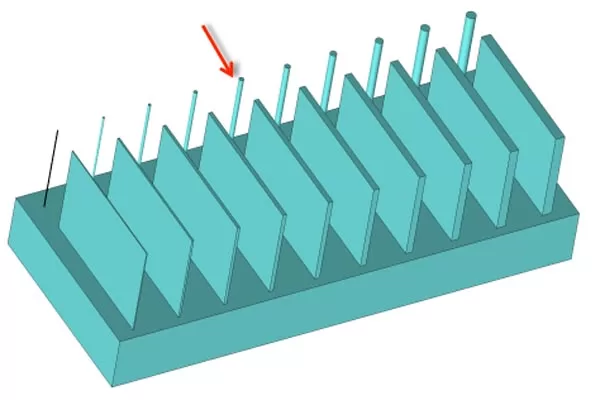

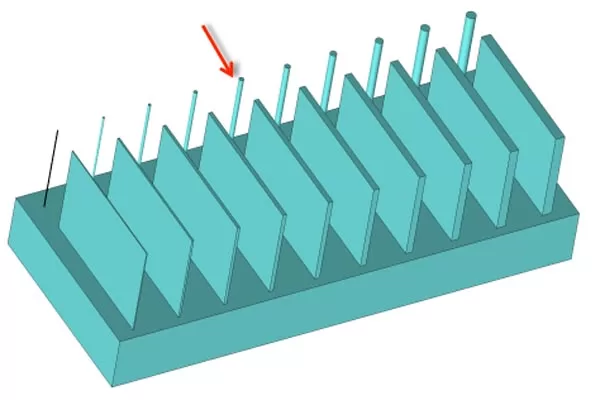

Design Guidelines for Direct Metal Laser Melting (DMLM) Although additive manufacturing (AM) removes many constraints of conventional manufacturing, it imposes some new constraints of its own. Always bear in mind that design for metal AM part is even tricky than...

by Nice Rapid | Jul 5, 2021

5 Most Common Resins Used in Plastic Injection Molding One of the reasons Plastic Injection Molding is so prevalent among the manufacturing processes is due to it offers a wide range of materials selection. This allows product designers and engineers able to create...